Search

Agricultural biogas plants use farm materials to generate biogas, a renewable fuel source, to produce green electricity and heat through Combined Heat and Power (CHP) / Cogeneration.

Agriculture biogas plants accept energy crops specifically grown to fuel the plant. Farm organic wastes and energy crops offer an environmentally friendly diversification for farms and offers many advantages.

The treatment for farm wastes, such as manure slurries and vegetable wastes in an anaerobic digester, would allow easier storage and a better fertiliser value when spread.

Production of renewable power through Combined Heat and Power provision

Disposal of problematic wastes

Diversion of waste from landfill

Production of a low-carbon fertiliser

Avoidance of landfill gas escape and reduction in carbon emissions

Agricultural crops such as maize, silage, grass silage, wheat and rye will boost gas production significantly, allowing a steady power production and predictable income return.

These inputs can also have benefits when grown as a break crop. The use of agricultural crops in a biogas plant is often the main driver to make a farm-based plant economically viable. Biogas production is, via the generation and sale of electricity, usually the main or only financial return for a plant.

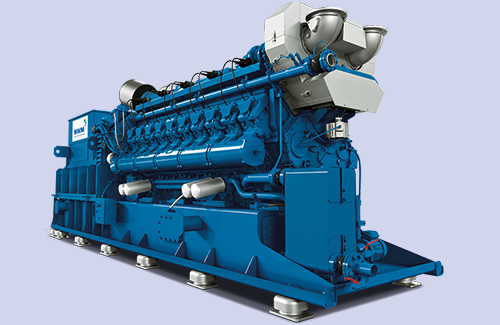

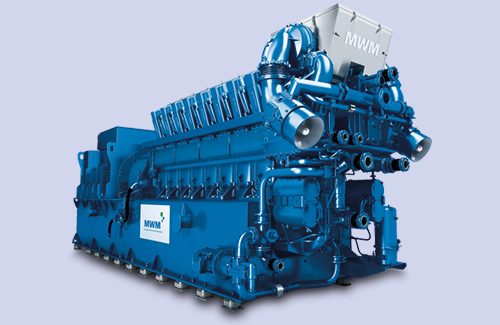

The agricultural crop will have a production cost making it even more important to extract the best value from the gas produced. Therefore a high-efficiency electrical conversion generation unit is needed, and the technical backup from the equipment supplier to ensure reliable continuous operation of the CHP plant over the project lifetime.

The Combined Heat and Power unit is probably the most vital link in the economic success of an agricultural anaerobic digestion project. The choice of supplier can be critical to project success.

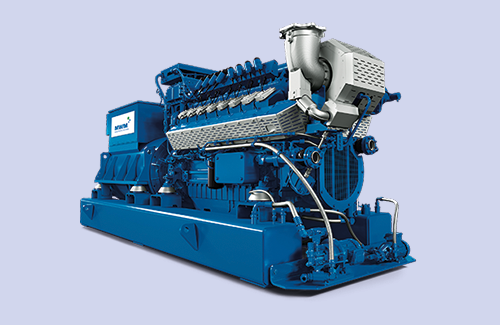

The MWM range of gas engines are perfectly capable in operating on biogas and our containerised solution is especially tuned for this application.

We have supported clients across a wide range of industry sectors to achieve energy efficiency, reduce emissions and operational costs, maintain power resilience, and improved business competitiveness.

Copyright © Edina. All Rights Reserved.