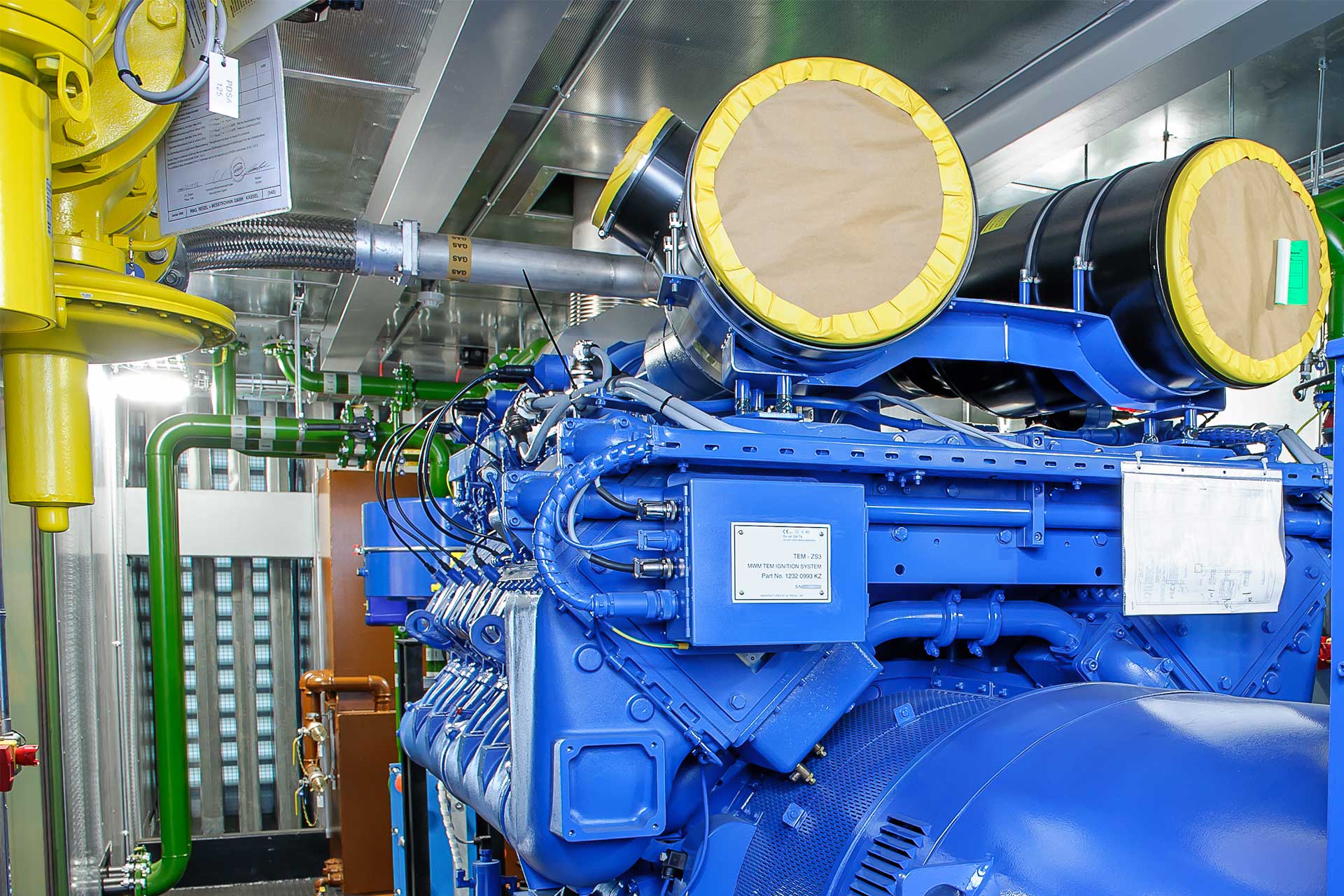

A power island energy solution can include a multi-generator configuration to accompany Combined Heat and Power (CHP) application, standby diesel power generation and a rotary Uninterrupted Power Supply (UPS) system.

CHP application offers the best solution to meet the growing heat and electrical demands of the facility. CHP also reduces a facilities carbon footprint and maintains a cost-effective management plan by reducing energy costs, providing a significant return on investment.

The CHP plant can operate in Island Mode, independent from the electricity grid. This, coupled with standby diesel power generation and rotary UPS system, provides a constant supply of power to the facility.

As the energy requirement of a facility grows, it faces challenges to meet its existing power infrastructure needs.

In some instances, it may not be feasible to demand additional electrical supply from the grid due to capacity issues. Although capacity issues are known and grid reinforcement are years away, it presents a major challenge for the industry to access additional electrical capacity from the grid.

If the wait for grid reinforcement is not an option, self-generation offer a practical and cost-effective solution to produce the power needed on-site.

Copyright © Edina. All Rights Reserved.