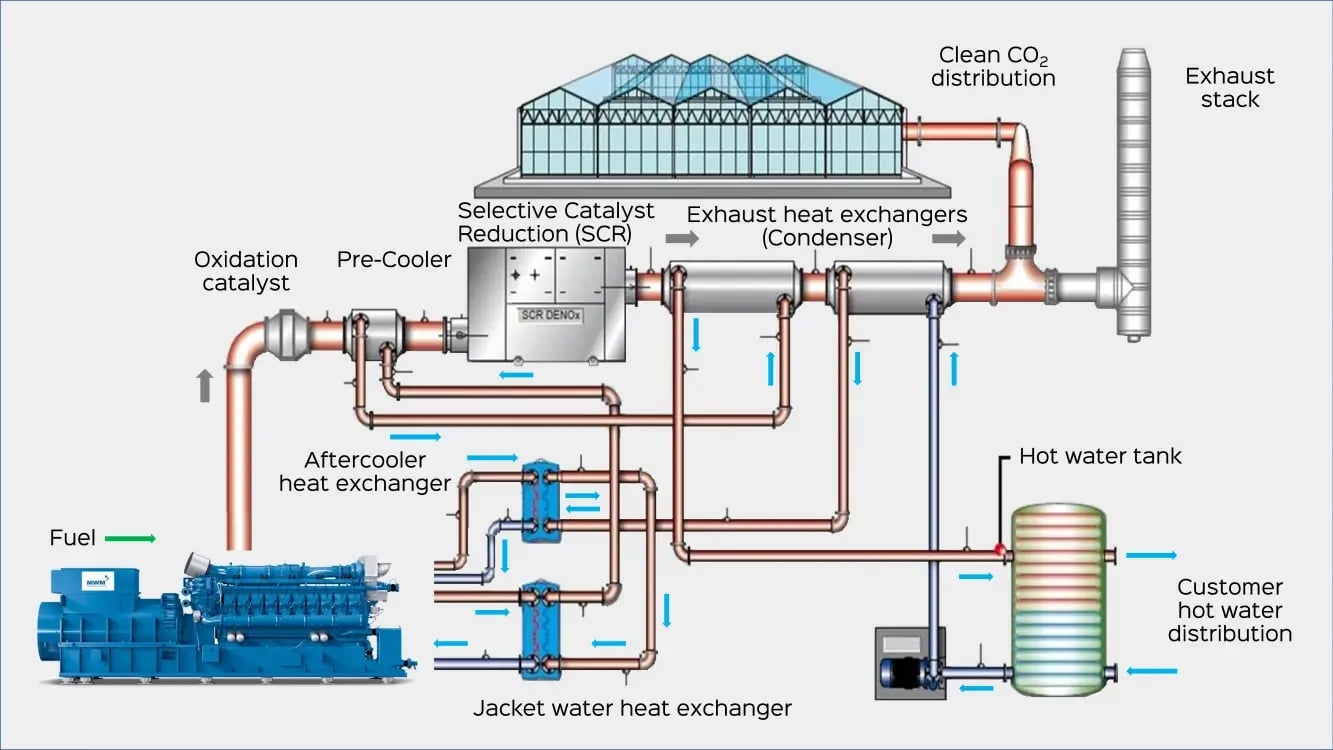

Greenhouses, glasshouses, plant nurseries and growers can use Combined Heat and Power (CHP) or Cogeneration to provide electricity, heat, and carbon dioxide within their horticultural facilities to stimulate photosynthesis. The electricity produced can be consumed on-site to provide lighting or sold to the electricity grid for income generation.

Reduced utility costs and emissions versus separate CO2, heat and electrical generation systems

Energy efficiency over 95%

High quality carbon dioxide crop fertilisation

Increased revenue opportunities through the export of electricity

Cost savings can be reinvested and deployed in renewable energy technologies

Fuel flexibility - renewable, low carbon, and hydrogen ready

Recognised technology within the net-zero pathway

As such, the electrical energy produced from the gas engine, alongside the recovery of heat or hot water, and CO2, all provide the right conditions to promote plant growth.

CHP offers the benefit of providing an “all in one” (electricity, heat, CO2) solution. The choice of solution needs to be considered relative to the growing requirements and the scale of the greenhouse facility. As such, CHP should be considered as an option in facilities over 10,000 m2 (1 hectare).

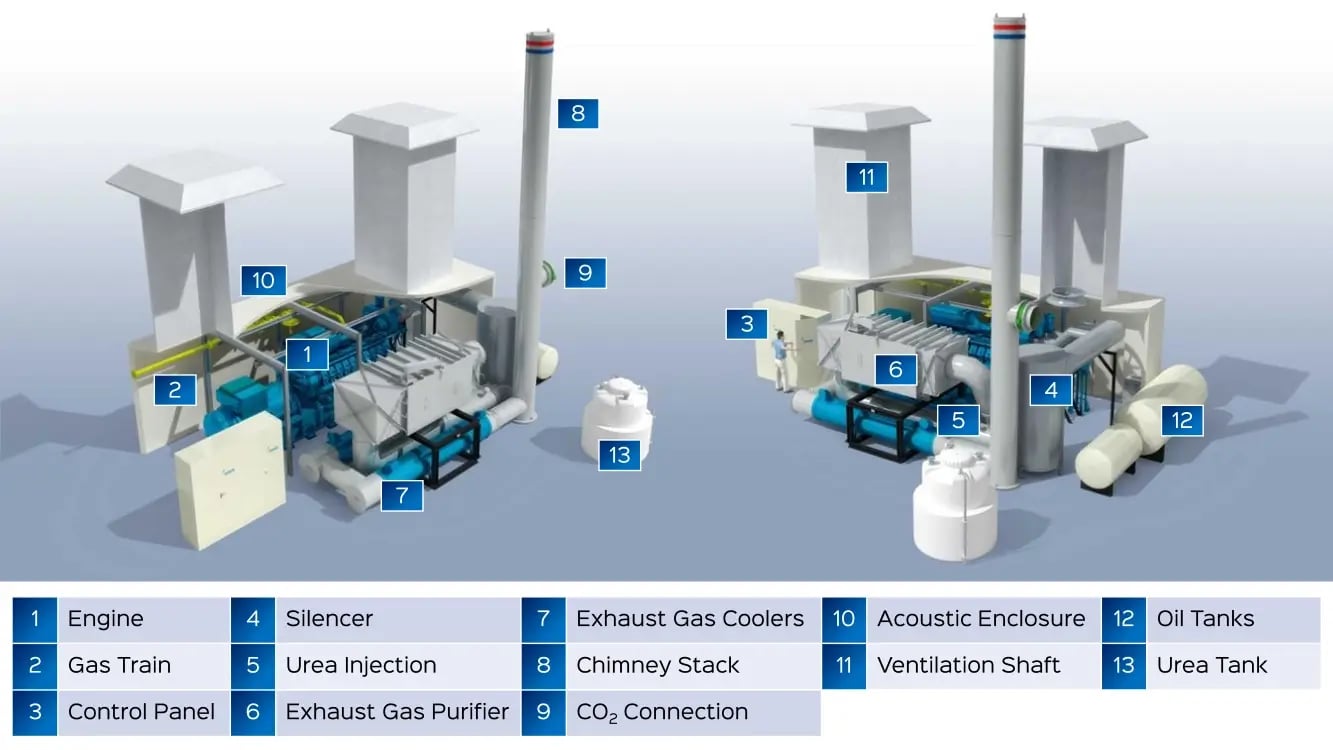

World-renowned gas engine manufacturer MWM continues to innovate, ensuring the future of Combined Heat and Power (CHP) and its critical role within the global transition towards net-zero and beyond.

As such, MWM gas engines are capable of 25% blended-hydrogen CHP solutions. MWM have significant development experience in hydrogen-fuelled internal combustion engines for more than 20 years.

Global carbon dioxide (CO2) levels are approximately 350-360 part per million (ppm) and research has shown that plant growth can improve by 40-50% with increased levels of CO2 up to 1200 ppm. Optimal CO2 levels will be dependent on the plant being grown.

In modern glasshouse horticulture, CO2 supplementation is a common and highly beneficial practice as the environment can be controlled to suit the plants being grown which allows plant yields to be maximised.

There are a number of ways to introduce CO2:

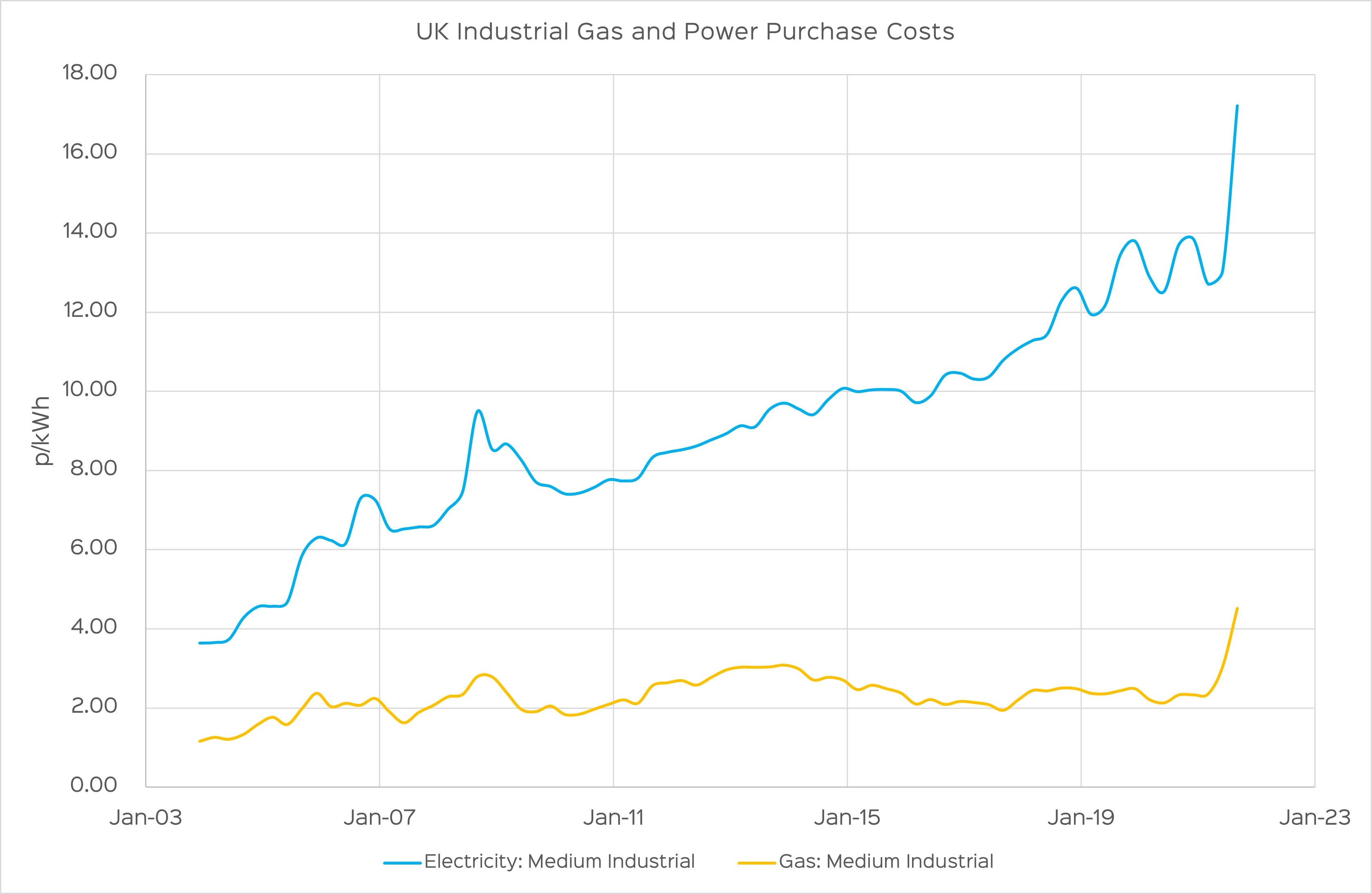

The reopening of industry following the lifting of COVID restrictions has created worldwide demand in gas and the ongoing conflict in Ukraine has further intensified market volatility which has resulted in unprecedented gas price increases.

The soaring price for gas has also significantly impacted electricity prices more so because gas is used to produce electricity, which accounts for roughly 50% of the UK’s energy mix. Worryingly, price volatility is likely to continue beyond 2023 and the cost of inaction will place significant cost burden onto growers without a fixed long-term contract or whose contract has expired.

Whilst both gas and electricity have increased, gas is consistently cheaper than the price of grid procured electricity. By using cheaper gas to generate power, growers can benefit from a positive spark spread. This cost advantage is underlined by the rapid return on investment of CHP systems, which often provide a payback within one or two years.

The recent UK Government Energy Bill Relief Scheme (EBRS) guidance for non-domestic customers provides support on their energy costs this winter and is expected to end 31st March 2023. We advise businesses to use this period of relief to investigate the suitability of on-site generation such as Combined Heat and Power (CHP) to secure costs are managed in the long-term and businesses remain financially sustainable.

By self-generating power on-site, growers can produce most of their electricity requirements, only drawing on grid supplies where necessary. This means that they have the flexibility to avoid purchasing network power at peak times when prices are vastly inflated.

As a market-leader in the supply, installation and maintenance of CHP, Edina has completed many energy saving projects across the Glasshouse sector.

Edina CHP helps Ireland’s leading tomato growers become more profitable.

Copyright © Edina. All Rights Reserved.