Combined Heat and Power (CHP) or Cogeneration (Cogen) is a well-established technology that simultaneously generates electricity and heat from a fuel input.

Cogeneration can save up to 30% on primary energy costs when compared to the separate purchase of electricity from the electricity grid and gas for use in on-site boilers.

CHP has been used for many years all over the globe across different industries in several forms (steam boilers and steam turbines, gas turbines, steam boilers and steam turbines, reciprocating engines and heat recovery systems). The arrangements selected are generally detected by the available fuel source, market sector and scale.

In the UK following the privatisation of British Gas in 1986 and the dash for gas in the 1990s, CHP in industry grew rapidly with the installation of gas turbines and steam boiler plants, and within the commercial sector and hospitals with the installation of gas engine plant. Today, due to the reduction in plant size and the requirements for greater operational flexibility gas engine CHP has become the leading technology of choice.

With the drive towards a sustainability zero carbon economy all the major manufactures have biogas and biomethane green gas engine variants and are future proofing their technology to use hydrogen (mixed or pure).

CHP is a proven technology and can deliver generation efficiencies up to 95% utilising low carbon natural gas as a fuel source. As the gas grids become green, the carbon signature of CHP will reduce. However, CHP can use zero-carbon fuels directly to deliver zero or a negative carbon position.

When businesses are planning the building of new facilities or improvements to existing, they should always consider CHP or Trigeneration, known also as Combined Cooling Heat and Power (CCHP). CHP can play a valuable role to support business to deliver a sustainable, secure, and flexible energy solution.

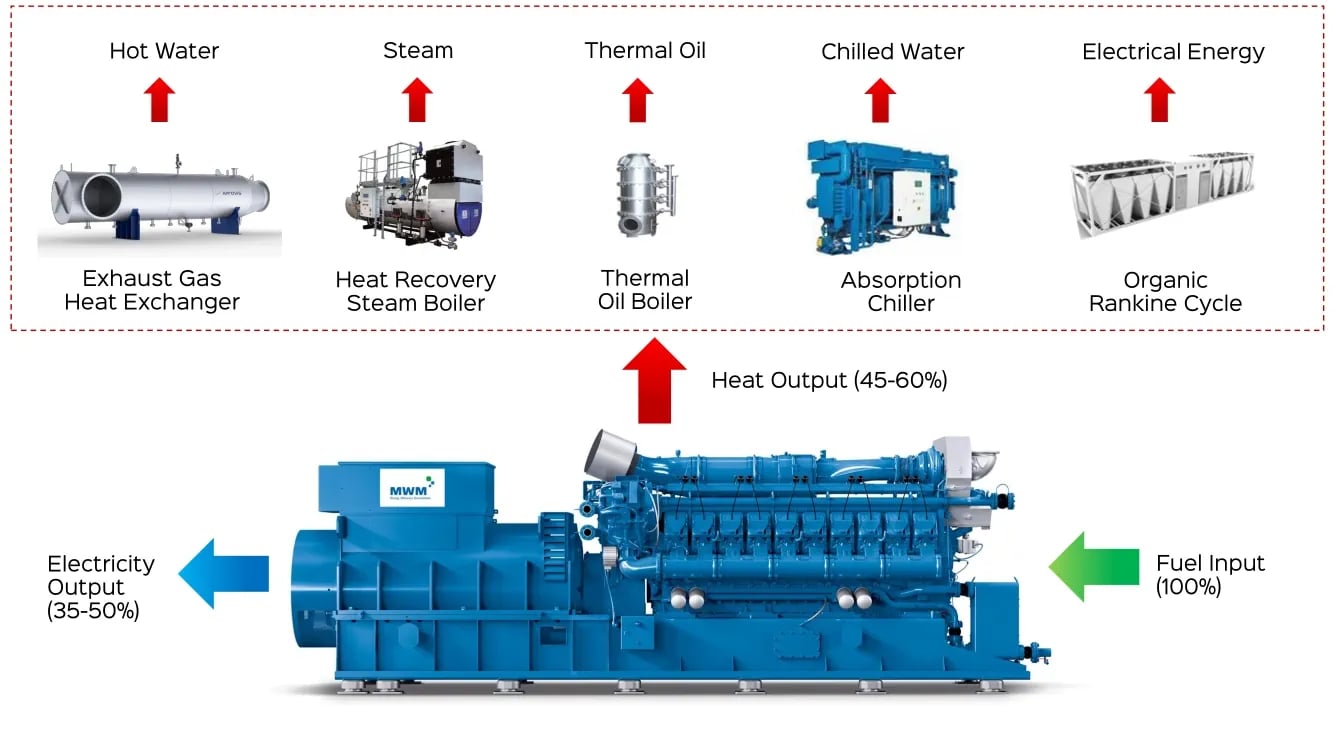

A fuel source (fossil or renewable) is combusted, and the energy produced is used to drive a prime mover (reciprocating engine or gas turbine) which produces mechanical power and heat. The mechanical power is converted into electricity via an alternator and the heat is available to use directly or converted to meet the requirements of the site.

For some applications a CHP system can achieve energy utilisation of up to 95%, typically they meet between 70-80% which is a significant improvement over importing grid electricity and conventional heat production. The improvement in the efficiency of energy production lowers the cost of production and where carbon fuels are being used as fuel it produces a lower carbon signature per unit of energy produced.

Further power efficiencies are achieved because the cogenerated electricity and heat is produced and consumed on-site, avoiding the transmission losses of around 7.5% that occur in transporting electricity from remote generators to consumers.

The price differential between, and depending on a site particular requirement, CHP can deliver improvement in energy efficiency, reduction in energy cost and an improvement in the site carbon signature. Depending on the fuel sources used (e.g biogas, hydrogen) CHP can deliver a carbon neutral or negative position.

Where sites have little demand for heat but require cooling for process, users can introduce absorption cooling into their CHP plant which can operate at temperatures as low as -5 deg C. This is called Combined Cooling Heat, Power (CCHP), or Trigeneration which can deliver cooling for air conditioning and refrigeration.

Where an organisation has a requirement for CO2 in their processes (glasshouse growers, carbonated drinks industry, food processing industry, brewing industry) the production of CO2 from the combustion of carbon-based fuels can be an economical consideration.

The term Quadgeneration has been given to CHP with the inclusion of equipment that takes the exhaust gases and processes them to meet the user requirements of the particular use. For a grower, this may be simple cleaning contaminants from the exhaust gases and cooling the gases, whereas for the food and drink industry requiring 99.99% pure CO2 this will require a more sophisticated processing plant.

If your organisation utilises power, heat, steam, cooling, and CO2 in your operations and processes, then CHP, Trigeneration, or Quadgeneration should be considered part of an energy strategy. It doesn’t fit every organisation, but where it does, CHP can deliver substantial benefits such as:

The above are just some of the many benefits of CHP compared to traditional means of separately generating power and heat.

Combined Heat and Power (CHP) should be considered:

A gas engine CHP system has a power to heat ration of 1 : 1-1.2 which means for every 1000kW of electrical generation, 1000-1200kW of heat will be available.

Businesses that have operational sites with a simultaneous requirement for power and heat or cooling (i.e. heat ratio of 1 : 0.5 ->1.2) for a long period over the year (i.e 6000 – 8000 hrs annual operation) are likely to benefit from the installation of CHP. CHP plants operating at 8000hrs and greater with power to heat utilisation of 1 : 1.2 and greater will deliver the best savings and lowest carbon signature.

When evaluating CHP for your site it is important to answer the below questions:

Q1. What is your current energy usage and predicted future energy usage? CHP systems deliver the best and most secure financial returns when available energy production is fully utilised.

Q2. What is your current energy pricing and predicted future energy pricing? The greater the spread between the price of imported electricity and gas (known as the Spark Spread) will deliver the greatest financial benefit. A positive Spark Spread of '3' or above usually indicates that the CHP project will be financially viable.

Q3. What is the current cost of operation vs cost of operation with CHP? The direct cost of including CHP should only be considered. In some cases, the inclusion of CHP can offset existing costs (for example the removal of boilers, chillers etc) which needs to be brought into your evaluations.

Q4. What are your investment requirements and additional investment for CHP? CHP is one of the few technologies that can provide a return on investment. When evaluating the economic performance of the CHP it should only include the plant directly associated with the CHP installation and not plant that is being upgraded or is required to provide security of service (e.g. standby plant, boilers, chillers, etc.).

Q5. What is your site's carbon signature pre and post CHP? Businesses have a requirement to operate sustainably. As such CHP can help to support achieve their goals when correctly selected and delivered.

Q6. Will the inclusion of CHP place the organisation into other areas of tax (for example the UK Emissions Trading Scheme (UKETS), Carbon Price Support (CPS))? Any additional administration and cost burdens must be factored into financial modelling.

Market pricing, Government initiatives and taxation must be considered in long term investments, they generally are complex and, in some cases, work against each other. They also can set thresholds where schemes are optimised against the financial performance and not the optimum environmental performance.

The Climate Change Levy (CCL) is an environmental tax charged on the energy that businesses use. It’s designed to encourage businesses to be more energy efficient in how they operate, as well as helping to reduce their overall emissions.

The CCL applies to businesses in the industrial, public services, commercial and agricultural sectors, and is charged on ‘taxable commodities’ for heating, lighting, and power purposes.

CCL is paid at either the main rate or Carbon Price Support (CPS) rate, the differences in which are detailed below.

Any business in the industrial, public services, commercial and agricultural sectors will be charged CCL at the main rate on electricity, gas, and solid fuel (e.g., coal, coke, lignite or petroleum coke) use. The CCL main rates are listed on your business gas or electricity bill.

Businesses exempt from paying main CCL rates include charities engaged in non-commercial activities and businesses that consume energy below the de minimis limit.

If you own generating stations or operate Cogeneration plants greater than 2MW electrical generation, then you will be required to pay the Carbon Price Support (CPS) rate. The levy rate varies for each commodity: kilowatt-hours for gas and electricity, and kilograms for all other taxable commodities.

Additional information can be found by visiting the UK government resources below:

If you are the operator of a CHP plant with a generating capacity of 2MW or below, you are considered to be a small CHP plant and don’t need to register or account for the CPS rates of CCL, as there’s no deemed supply when a quantity of a CPS rate commodity is delivered to the site of the CHP plant.

The generating capacity is specific to each individual CHP scheme registered under the Combined Heat and Power Quality Assurance (CHPQA) Programme. Therefore, when you calculate the capacity for your CHP station, you should not take into account any other stations you operate or that are operated by any person connected with you, apart from those that are covered by the same CHP scheme.

CHPs registered under the Combined Heat and Power Quality Assurance (CHPQA) scheme with a generating capacity of 2MW or above who use CPS rate commodities as input fuels, are liable to account for the CPS rates of CCL on the proportion of a quantity of a commodity that is the subject of a deemed supply. CPS rate commodities don’t form part of the deemed supply when intended for use in producing:

The proportion of the commodity that is the subject of a deemed supply is initially provisional. This is because the status is based upon the current CHPQA certificate. This CHPQA certificate records the actual performance of the CHP plant for the previous calendar year. Once the CHPQA certificate for the annual operation covering the CCL return period is received you must review the status of commodities in that return period and adjust the declared liability accordingly.

The UK government provides support for CHP as it is viewed as and energy efficient solution that can provide significant efficiency benefits over conventional sources of supply. CHP plants must achieve “Good Quality” status under the Combined Heat and Power Quality Assurance Scheme to qualify for a range of financial incentives including exemption from the Climate Change Levy (CCL). CHP plants that are awarded ‘Good Quality’ status can register for CCL exemption - the level of fuel that is exempt for CCL is dependent on the performance (efficiency and heat utilisation) of the scheme for very high performing CHP plant additional gas burning plant (e.g. boilers) can be brought into the CHP boundary which offers greater saving.

CHP offers businesses operational flexibility to take advantage of additional revenue streams being introduced to manage Grid operation with the roll out of renewable technology.

By generating electricity on-site and procuring some from the electricity grid, organisations gain more flexibility over how they purchase energy. This unlocks several advantages, including:

The value of these benefits can be further enhanced by using a CHP system in combination with battery storage.

CHP systems are available with a range of flexible finance options, depending on the financial structure projects can be funded off balance sheet. These include:

Financing can be tailored to meet organisations specific requirements, to meet short term and long-term business objectives.

CHP is a combination of technologies designed to deliver power and heat. The fuel source utilised in the combustion process determines whether it is classified as renewable or low carbon. Gas engine CHP can accommodate low-carbon natural gas, renewable fuels such as biogas, biomethane, syngas, sewage gas, and hydrogen, for when it becomes commercially available. Other CHP technologies can accommodate solid biomass and liquid biofuels.

Within the UK and Ireland most CHP plants are based on gas engine primemovers which are fuelled by low carbon natural gas, biogas and biomethane. According to the latest statistics published by the Digest of UK Energy Statistics (DUKES), in 2020 natural gas remains the main fuel consumed by CHP schemes representing 72% - up from 69% in 2019, with renewables accounting for the next highest share at 15%. Fossil fuels other than gas now account for just 7.5%.

Biomethane, also known as renewable natural gas, is produced from biogas that is derived from organic matter such as food waste, wastewater sludge, animal manure, or agricultural waste. As part of the biogas upgradation process, CO2 and other contaminants are removed to produce a renewable fuel.

Users looking to fuel their CHP plants using biomethane can apply via the Green Gas Certification Scheme (GGCS) – a subsidiary set up by the Renewable Energy Association to ensure and trace biomethane, or ‘green gas’, through the supply chain to certify its origin for users that buy it.

In this way the GGCS eliminates double counting of registered green gas within the supply chain to ensure the biomethane contracted has been procured from registered and accredited biomethane producers.

Each kWh of biomethane is electronically tagged with a unique identifier known as a Renewable Gas Guarantee of Origin (RGGO). This identifier contains, for each kWh of gas, information about where, when, and how it was produced. When consumers buy green gas the RGGO is their guarantee that the gas is authentic and has not been sold to any-one else.

According to the UK Hydrogen Strategy policy paper published 17th August 2021, it is understood the UK government will prioritise hydrogen application for transport, large energy users and heat.

Below is an excerpt from the document (page 57) outlining its potential within CHP plants:

Initially, hydrogen will likely be used to fuel indirect heating technologies such as steam boilers and CHP units. Given the range of sectors that use steam as part of an industrial process, our analysis indicates that boilers and CHPs could make up around two thirds of demand for hydrogen fuel switching by 2030. We will therefore focus on policies to unlock the fuel switch potential for these technologies, taking into account replacement cycles of existing equipment. Work is ongoing to establish the role of hydrogen in decarbonising CHPs.

How hydrogen develops as an energy source within the UK is unclear and will take many years to come to commercialisation. However, initiatives are taking place to develop:

The outcome from these initiatives will help shape the direction of the evolving hydrogen market. CHP is well placed to not only provide a viable technology during the transition phase to green energy but also when the transition is complete.

Equipment manufacturers have taken the challenge to adapt their technology to operate on hydrogen/natural gas mix and 100% hydrogen, which ensures that investments in CHP technology are secure.

Today, operational CHP plant can accept hydrogen blends of up to 25% within the current gas network. With a 25% hydrogen fuel blend, a further 7% reduction in CO2 can be achieved.

.jpg)

CHP makes a major contribution to the UK energy mix, generating 7.9% of total electricity supply, according to the latest government data.

Sites with a high and consistent heat/cooling and electricity load profile can maximise CHP savings due to high efficiency. However, the strong economics of gas-fired CHP engines means that many sites with a smaller demand profile and lower heat demand are also suitable.

Cogeneration and trigeneration benefit a wide range of organisations across many sectors, including:

Major energy consumers operating in competitive global markets, including manufacturers and companies involved in industries like chemical, oil and gas, and paper and publishing, can often derive huge benefits from CHP. Collectively, businesses in these sectors account for a significant majority of cogeneration capacity in the UK.

CHP systems can be installed in existing structures or new purpose-built facilities. There are four main categories that meet different specifications and meet different long-term power objectives.

Containerised power plants offer a plug and play approach and can be mobilised at sites where there is no internal structure to house the gas engine generating asset or containerised within a building to meet the noise requirement. A containerised power plant is generally used for units ranging from 400kWe through to 2,300kWe.

Advantages of containerised power plants include:

Generally used for large scale projects, including municipal and district heating schemes, a purpose-built energy centre can be used to house multiple CHP gas engines or a combination of energy technologies.

Advantages of CHP energy centres include:

For projects where space is limited or planning may be a problem, gas engines can be installed inside existing structures. Retrofitting CHP units can be done inside a main building or in supplementary outbuildings, like an old boiler house.

Advantages of using gas engines within an existing building include:

Should the energy requirement of a facility grow it could potentially face restrictions from the grid to draw additional capacity. If the wait for grid reinforcement is not an option, businesses can generate their additional power via on-site gas fired generation witin a power island configuration.

Advantages of a gas engine CHP power island:

There are several important considerations that are important to maximising the potential benefits of a CHP project. These include:

We’ll consider each of these issues in turn and explain how you can make the most of CHP at the site.

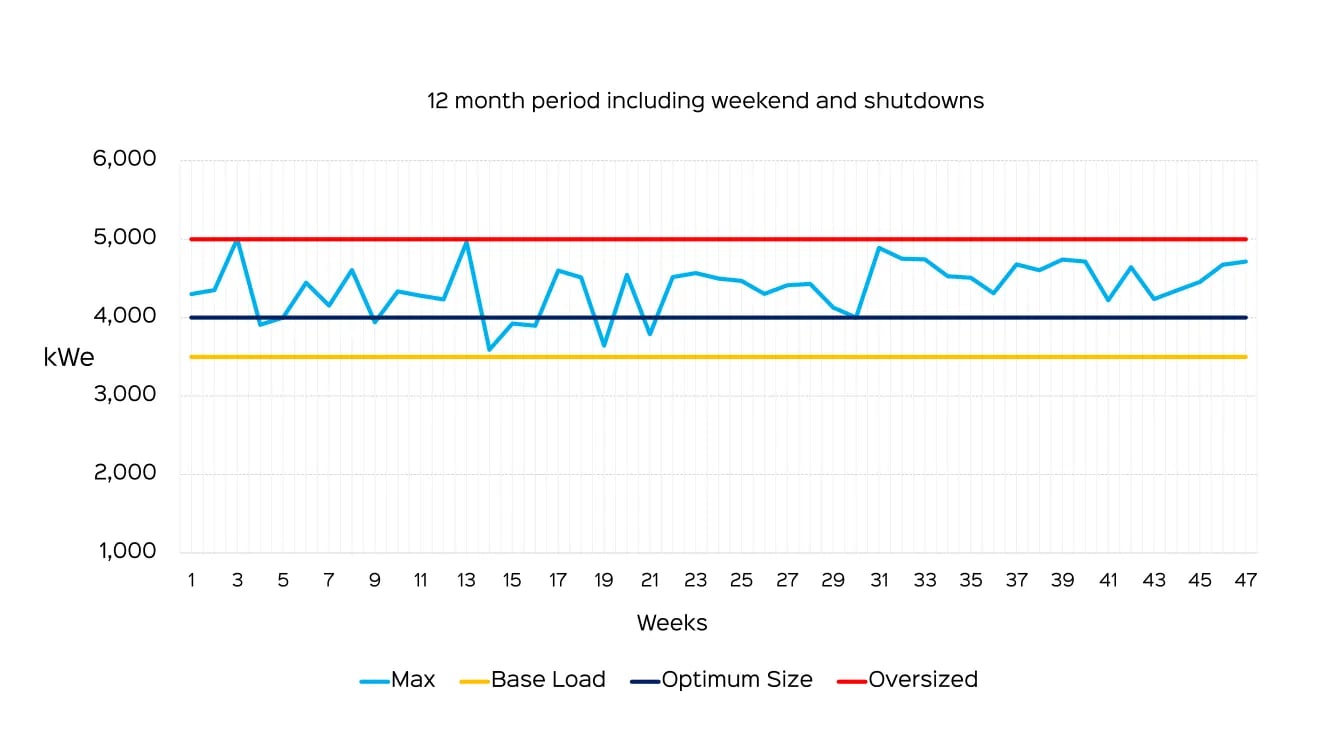

The energy efficiency and cost savings associated with CHP can reduce if a project is not sized correctly. Make your scheme too big, and it won’t run at maximum efficiency. Make it too small, and you could miss out on the financial benefits of maximising low-cost self-generated power.

CHP specifiers need to consider several variables before selecting an appropriate engine. It’s important they understand some of the underlying motivations behind the project as well as cost and carbon requirements.

If your motivation is to maximise the CHP system efficiency, there is no need to size a plant for the highest peak electricity or heat demand. If a CHP plant can cover 100% of peak annual energy demand, then the unit will be running at reduced capacity for most of the year.

CHP generators are less efficient when operating at a reduced load.

Running at maximum efficiency, a CHP unit will only generate enough heat and power to meet a site’s base load demand.

Power and heat from the CHP system can be topped up with additional electricity from the grid and heat from existing boilers to meet peak demands and optimise performance.

From a commercial (rather than a pure efficiency) perspective, the optimum engine size would provide slightly more than the base load. It would be sized to run at a full load for as long as possible, maximising the economic benefits of self-generation and resulting in only minor energy wastage.

Although wasting heat makes CHP less efficient, the financial benefits of self-generated power mean that it can be worthwhile to run CHP at a high electrical load, even if heat demand is relatively low.

This may only be true up to a certain point, however, because inefficient CHP systems risk missing out on certain tax incentives like an exemption from the Climate Change Levy and eligibility for the Annual Investment Allowance if they do not meet CHPQA efficiency standards.

For some sites, the amount of wasted heat can be reduced by:

Correctly sizing a CHP system means closely matching a unit to a site’s energy load. This requires careful analysis of a site’s energy demand over time.

Energy consumption data can come from several sources. To build a clear picture of energy consumption, it is preferable to use half-hourly metering data or information from a building energy management system.

Plotting electricity and heat consumption over time will produce a pattern showing how and when energy is used. It will also show up variations in demand at different times of day, during the week and across the year. Mapping these variations is crucial to finding the optimum level at which a CHP unit should be operating at maximum output.

If you are trying to size a CHP system for a new building, then demand profiles can be estimated using a range of sources including design data, occupancy patterns, simulation modelling and benchmark profiles from comparable projects.

Using inaccurate energy data is one of the biggest causes of under or mis-sizing a CHP project, so take care to make sure this data is a true representation of real life.

Natural gas is the main source of fuel used in CHP systems in the UK and Ireland. It has a high heat value, so is ideally suited to on-site power generation, but each CHP project will have a number of considerations based on a site’s available gas supply.

A reliable gas supply is critical to success. Mains gas pressure varies significantly across the UK and Ireland. In the project planning phase, specifiers must make sure the local gas supply network can meet the pressure demands of a CHP engine.

Gas compressors can provide a pressure boost if the local supply is too weak, but this will incur extra capital and running costs and could make on-site gas generation unsuitable.

Gas-fired CHP will significantly increase a site’s natural gas demand. If the installed network cannot cope with the additional volume demand, then the supply infrastructure may need to be upgraded.

If a site connection cannot meet the new peak requirement, it may need to be updated, or a separate gas supply may need to be opened up to serve the CHP plant. Any supply issues will need to be raised with the local gas distribution network.

The quality of natural gas is regulated, but composition can vary from location-to-location. Small variations in quality are not usually sufficient to affect on-site gas generation, but it could have a small impact on efficiency. Over time, this small discrepancy will need to be factored into output calculations.

Specifiers can judge the quality of gas at a site by measuring the composition of gas and using it to calculate quality parameters, like calorific value.

A new energy centre, containerised gas engine or existing building CHP installation may need to be approved by the local authority. Planning permission can be easier or more difficult to obtain based on the site’s local area.

If a site is in a residential area, or close to a major city, the building design may need to be altered to reduce the impact on the local community. In more industrial areas away from large population centres, planning permission is generally easier to attain.

The noise a CHP unit makes is a key consideration, particularly when there is a residential dwelling nearby.

The impact of noise can be reduced by situating a CHP unit as far away from residences as possible. Alternatively, noise abatement solutions can be added to an energy centre or containerised gas engine, which can make the units more expensive.

This is often a straightforward procedure that can also look at other aspects of the installation such as the height of the exhaust gas flue systems. This aspect is regulated through a D1 calculation and dictates the height of the flue requirement.

Local gas dispersion may also cause an issue with a local authority. In some cases, dispersion modelling must be carried out to discover how dispersion will affect the area.

If local pollution levels are particularly high, or prevailing winds will have a serious impact on a local community, adjustments may need to be made to the exhaust gas flue system.

The Medium Combustion Plant Directive (MCPD) places a limit on the amount of nitrogen oxide (NOx) released from combustion generators in the 1-50 MW range in England and Wales. This can cause an issue for some plants close to major cities – particularly those in or near London.

CHP providers will ensure that all installations meet the MCPD restrictions. In some cases, selective catalytic reduction technology can be used to reduce emissions, though this can increase CHP running costs.

A Distribution Network Operator (DNO), or a Distribution System Operator (DSO), is a company responsible for distributing electricity throughout the UK and Ireland. The DNO own and operate the system of cables and infrastructure that transport electricity from the national transmission network to homes and businesses.

To connect your CHP plant to the electricity distribution network, you must apply to the local Distributed Network Operator (DNO) by following the G99 connection procedure.

The Data Registration Code of the Distribution Code sets out the obligations on the generator and Distribution Network Operator (DNO) to exchange data as part of the design process and lists the data items that may need to be exchanged. The purpose of completing the application process is to simplify and clarify this data exchange process.

For guidance on connection of generation assets to the UK and Ireland electrical network you should visit the Energy Networks Association (ENA), who are the industry body representing energy network operators within these territories.

Understanding the asset-care regime conducted by the CHP installer is as important as the capital installation project. With a typical gas engine plant expected to be in operation for more than 15 years, appropriate and routine asset-care maintenance is critical to ensuring the solution provides the ability to maximise commercial benefits and sustainability requirements.

Typically, CHP engines are installed at sites where management of energy costs and plant performance is key. As such, businesses do not wish to detract from core activity by having to operate and/or maintain their installation directly.

We advise engaging with a CHP solutions provider who can maintain the CHP asset on your behalf ensuring regular servicing and maintenance is carried out as per the manufacturer-recommended service intervals to ensure high availability and efficiency of gas engine CHP. Carrying out a thorough maintenance regime will unlock the full cost and carbon benefit of the CHP plant.

Dedicated CHP suppliers will offer a range of tailored asset-care agreements ranging from 12, 15 or 16-year life cycles and guarantee a minimum engine uptime availability, typically around 91 percent which is considered the industry standard. In-market location-based field service engineers will be able to carry out frequent routinely maintenance to ensure downtime is kept to a minimum.

As such field service engineering teams will be supported by 24/7 365 remote monitoring coverage allowing teams to have full visibility of the CHP engine performance. This includes continual monitoring of key performance indicators, such as electrical output and gas quality. Vendors with remote monitoring capabilities will allow faults to be identified and diagnosed sooner. In some cases, problems can be fixed remotely, cutting maintenance and call-out costs.

Using genuine Original Equipment Manufacturer (OEM) parts will enable the CHP plant to operate at its optimum performance. OEM parts are produced directly by the engine manufacturer at a high-quality standard and are designed to fit the engine to ensure safe and reliable operation and performance

Many aftermarket parts use low-quality materials and may save your money in the short term but will likely need replacing more frequently, causing unnecessary engine downtime and increasing long-term costs. Genuine OEM parts are readily available and backed with manufacturer warranty support providing additional peace of mind.

Understanding your business’s requirements will determine the success of your CHP solution. Many companies offer a CHP unit as a standalone product, and other providers will deliver a comprehensive CHP solution that includes detailed design, engineering, life-cycle services, and project financing.

Therefore, understanding your goals will determine the scope of work required. A few examples are below:

Once you have a clear understanding of your business requirements, the simplest way to gather information on CHP suppliers is to conduct internet desk research. Gathering information on office locations, the number of employees, department teams, and capabilities will help form an initial assessment and select suppliers who best fits them.

When reviewing CHP supplier capabilities, it is important to consider:

Take time to contact the suppliers and where possible arrange a face-to-face meeting, where the suppliers can present their company profile and capabilities and your team can assess if they are a good fit for your business.

Copyright © Edina. All Rights Reserved.