Search

Propane fuelled Combined Heat and Power (CHP) systems can produce electricity and heat on-site and reduce site dependancy on costly grid procured power and gas for on-site boilers.

CHP plants fuelled by propane are typically installed in any location regardless of their proximity to gas infrastructure. Propane is conveniently easy to liquefy under pressure and stored within storage cylinders that can then be transported as liquefied petroleum gas (LPG) to customers via truck, rail, or sea.

Propane is declared as a high-quality gas and therefore the longer service intervals can be expected

Commercial Propane contains no contaminants like sulphur, which would harm the engine

The engine is independent of natural gas pipelines

Propane is typically stored in large tanks and can be used to operate the engine independently and remotely from any infrastructure

Due to the low boiling point large amounts of energy can be transported and stored in liquefied form easily and safe

Propane is a colourless, odourless gas which belongs to the alkanes. Since propane liquefies at a relatively low pressure, even at normal temperatures, large amounts of energy can be stored in the liquid phase.

Because of the solubility of alkanes in one another, DIN 51622 defines the common technical propane on the market as a mixture of at least 95% propane and the rest a mixture of ethane, ethene, butane and butene.

HD-5 standard is defined as propane with maximum 5% propene / propylene and not more than 5% of butanes and ethane. Hence, 99% propane and 1% propylene can also be labelled as HD-5 propane. The limits are important, because higher amounts of propylene can cause problems in engines. To use the also available HD-10 propane gas for example, a technical approval is required.

Liquefied Petroleum Gas is a mixture of propane and butane. Depending on the region and the time of the year, the ratio may vary from 5% butane to 40% butane.

Through extraction from the liquid phase of the tank and complete evaporation, an increase in concentration of liquid components can be counteracted.

Together with other alkanes like methane, ethane and butane, propane is a part of natural gas.

During the processing of natural gas all hydrocarbons besides methane are filtered to a certain degree. Otherwise, non-methane hydrocarbons could change to the liquid phase and damage the gas pipeline equipment.

Furthermore, natural gas is industrially cleaned from contaminants like CO2 and H2S. Therefore, propane is a high-quality product of gas processing – a pure and precious fuel gas.

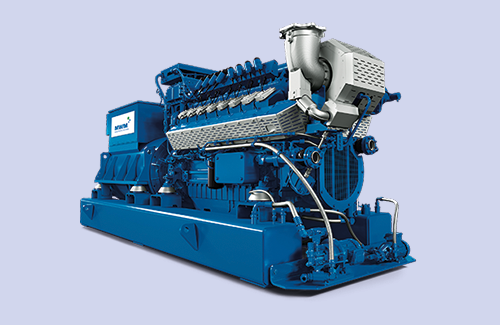

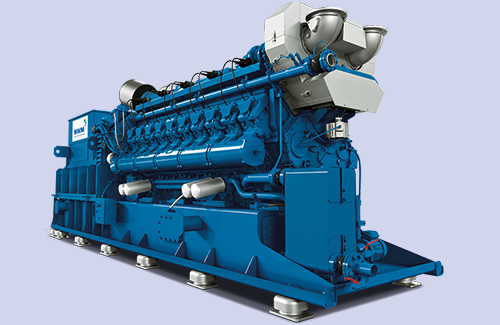

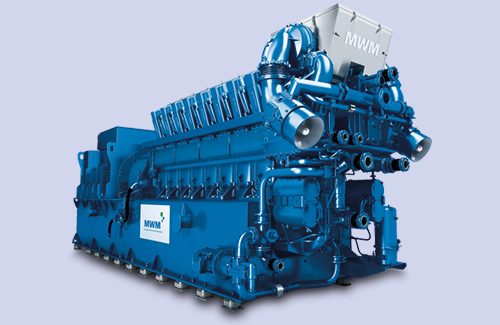

The MWM range of gas engines are perfectly capable in operating on propane gas and our containerised solution is especially tuned for this application.

Copyright © Edina. All Rights Reserved.