An energy study by NIFES Consulting Group was undertaken at Chorley and South Ribble Hospital for Lancashire Teaching Hospitals NHS Foundation Trust.

An energy study by NIFES Consulting Group was undertaken at Chorley and South Ribble Hospital for Lancashire Teaching Hospitals NHS Foundation Trust.

The opportunity to reduce both CO2 and energy consumption was identified with the incorporation of a combined heat and power (CHP) installation. The most economically viable option was to install a unit with an electrical output of 600kWe with the exhaust and jacket recovery configured for low temperature hot water (LTHW) thermal generation.

Edina was awarded the contract in mid-2011 with selection based on the high electrical efficiency achieved from the MWM manufactured TCG 2016 V12 reciprocating gas engine, which combined with a fully inclusive maintenance contract, provided the Hospital with the lowest lifecycle operating cost. Other significant factors were Edina’s ability to deliver a total turnkey solution and their proven track record within the Industry Sector.

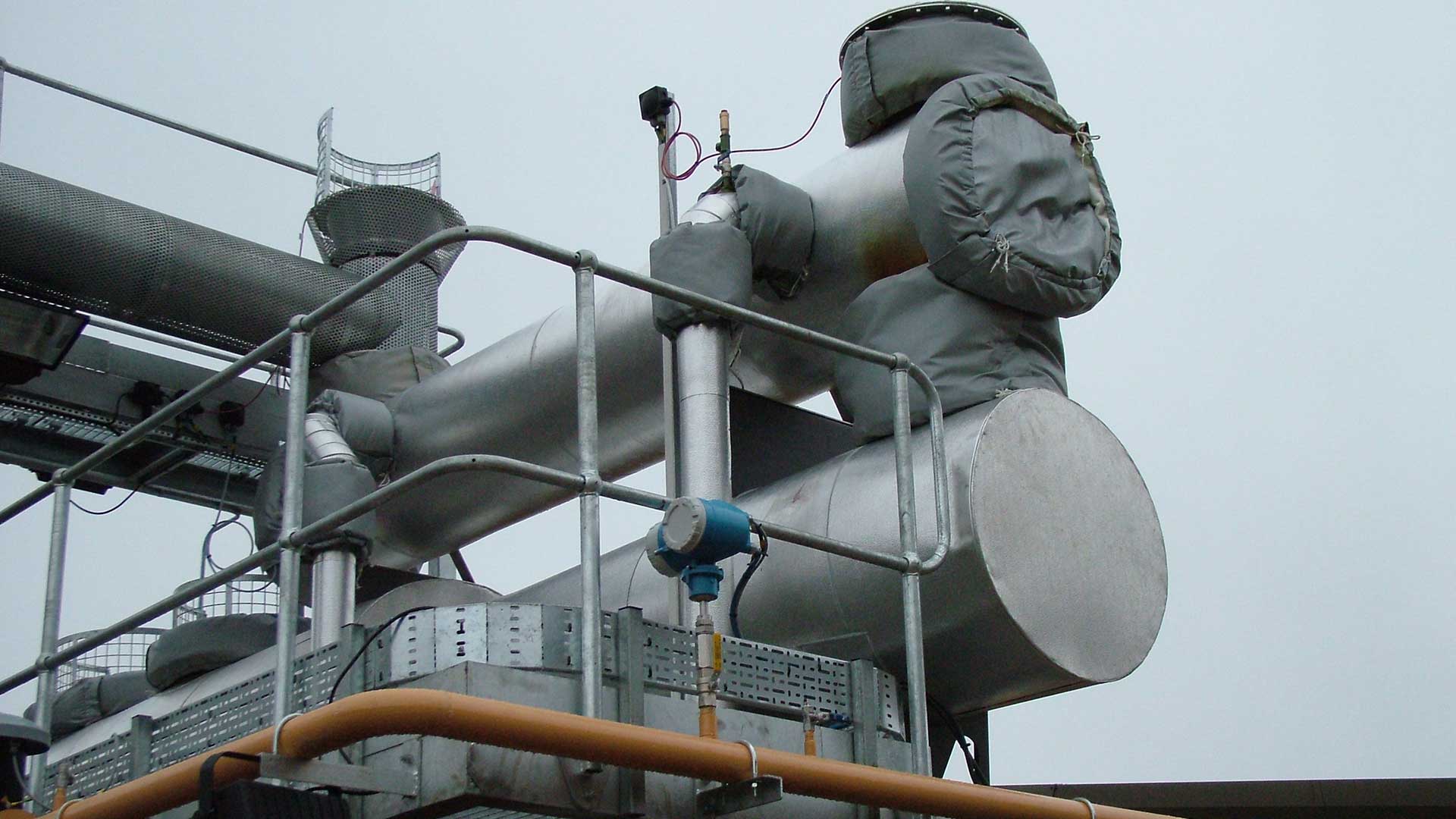

The Turnkey contract included the 600kWe MWM engine housed within a containerised acoustic attenuated enclosure installed adjacent to the existing boiler house with the balance of plant including engine heat recovery system, exhaust system and stack.

Full mechanical and electrical integration, BMS integration and civil construction were required making Edina fully responsible for the whole life operation of the supply contract.

The project commenced mid 2011 with Edina taking on the full construction and design responsibilities as required under Construction, Design and Management (CDM).

A dedicated Project Manager was assigned to coordinate the day to day responsibilities and to provide continuity of contact at site between all contracting parties and the client.

Careful consideration had to be given to the stringent noise levels imposed by the Hospital. The final solution was to provide the unit in a weather proofed enclosure with a certified noise emission of 60db (A)/1m. The success of this design was demonstrated by an independent noise consultant’s report.

The jacket water and exhaust gas heat recovery are combined to provide a total of 628kWt heat which serves the hospital’s existing central thermal load.

During the summer months, the CHP provides the majority of the hospital’s thermal load and during winter provides a significant contribution to the site’s base load.

The total system was commissioned and handed over to the client in March 2012 and achieves an electrical efficiency of >42 per cent with an overall system efficiency of >87 per cent.

The system has reduced the hospital’s CO2 emissions to approximately 817 tonnes per year, maintains security of power at site and expects to save the over £125,000 per year for the Lancashire Teaching Hospitals NHS Foundation Trust.

Client:

Lancashire Teaching Hospitals NHS Foundation Trust

Location:

Chorley, UK

Capacity:

600kWe

Operational:

2012

Manufacturer:

MWM

Packager:

Edina

Engine Type:

TCG 2016 V12

Primary Fuel:

Natural Gas

Copyright © Edina. All Rights Reserved.