Dynex, a world-leading designer and manufacturer of high-power semiconductors and assemblies, is benefiting from an Edina installed and maintained Combined Heat and Power (CHP) solution as part of its sustainability measures.

Edina, a distributed energy solutions provider, was contracted to design, engineer, install, commission, and maintain the 1.56MW electrical output Combined Heat and Power (CHP) plant at Dynex Semiconductors’ Lincoln manufacturing facility. This was initially instigated by in Dynex engineering and an external consultant who conducted the feasibility study.

The move to accelerate on-site generation CHP was driven by the volatile energy market and the need to manage rising energy costs, reduce carbon emissions, and improve energy-efficiency measures at the site by replacing old inefficient gas boilers.

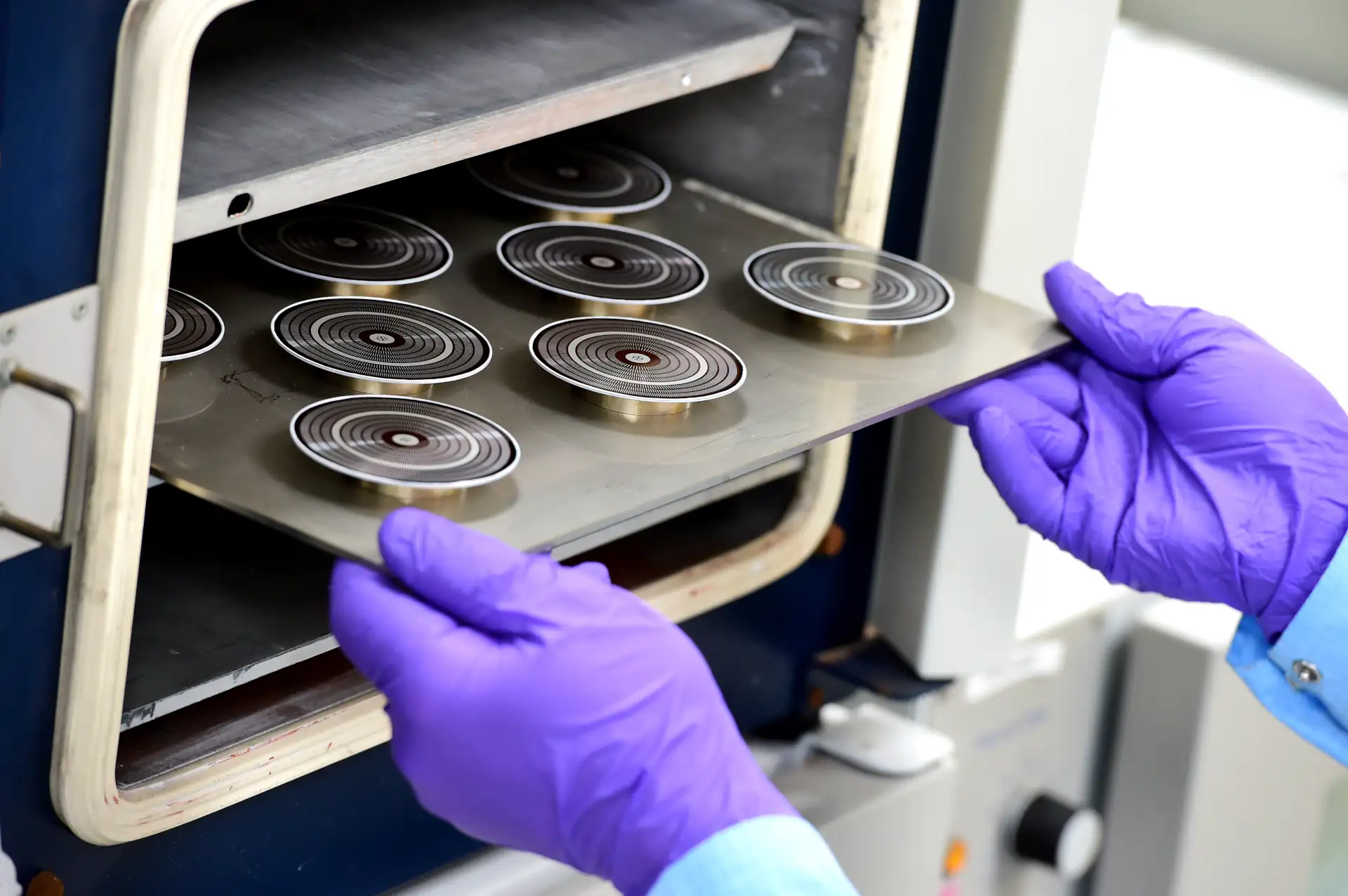

Dynex is one of the world’s leading manufacturers in the design, development and production of High-Power Semiconductor modules and Power Assemblies used within industrial, traction, renewable and power grid, electric vehicles, fusion energy, and hydrogen electrolysis applications.

The CHP plant, powered by a single MWM TCG 2020 V16 gas engine, produces 65% of the site’s electrical requirement, thus offsetting grid imported power. The heat from the electrical generation process is captured and utilised on-site to provide 90% of the hot water demand for temperature and humidity control within the manufacturing areas. In doing so, CHP provision reduces the boiler house demand for hot water generation and energy costs on-site.

Combined Heat and Power (CHP) is the cogeneration of electricity and heat from a single fuel source. CHP forms part of Dynex’s sustainability and low-carbon measures to improve energy efficiency and reduce its carbon and water footprint. The CHP plant offers high-efficiency energy utilisation of 95%. Because electricity and heat are produced and used on-site, Dynex will avoid transmission and distribution losses – typically around 7.5% that occur in transporting electricity from the grid.

Further sustainability measures include 300kW roof-mounted solar PV, which generates an average of 19,6423kWh/year, site-wide LED lighting rollout, and improvements in waste recycling. These are just some of the measures enacted as part of Dynex’s commitment to the UK Government’s Climate Change Agreement (CCA) which sets energy reduction targets for the semiconductor industry.

As principal contractor, Edina designed and engineered the CHP engine within an acoustically treated weatherproof enclosure for ease of installation and ongoing asset-care access. Edina delivered, installed, and commissioned the Dynex CHP plant on time and within budget and is maintaining the plant over a 15-year life cycle.

According to the latest 2022 plant availability performance data, the Dynex CHP is averaging a strong hourly availability at over 98% set against a 92.5% industry standard benchmark.

As the authorised official distributor for MWM gas engines, Dynex are benefitting from Edina’s in-market support leveraging its local field services engineers, 24/7 remote plant monitoring and conditioning, and access to genuine MWM parts to ensure the CHP plant remains operational and downtimes are at a minimum.

Working with Dynex and their incumbent mechanical team, Edina were challenged with dovetailing the programme for civil works, CHP installation and commissioning, with Dynex’s own extensive programme to overhaul the full heating and power networks within the site.

From civil works design and installation to lifting operations and final operational testing, both Dynex and Edina worked in synergy to ensure minimum impact to ongoing operations. A further testament to both teams that the project delivery took place during the COVID Pandemic and the unique challenges this posed.

The Dynex CHP plant is fuelled using low-carbon transitionary natural gas and can accommodate hydrogen admixtures of up to 10% without modification to the MWM gas engine. As the gas network greens up and greater concentrates of hydrogen blended into the existing gas network, the MWM gas engine can accommodate 25% hydrogen blends with some technical modification to ensure the safety and best-possible performance and efficiency of the energy generation.

Client:

Dynex Semiconductors

Location:

Lincoln, UK

Capacity:

1.56MWe

Operational:

2021

Manufacturer:

MWM

Packager:

Edina

Engine Type:

1 x TCG 2020 V16

Primary Fuel:

Natural Gas

Bausch + Lomb CHP plant reduces annual operational costs by €1million for global eye health company.

Read moreEdina saves Ice Cream Manufacturer a mouth-watering £440,000 a year while ensuring security of power.

Read more

Copyright © Edina. All Rights Reserved.