New combined heat and power (CHP) plant at the University of York provides the campus with low cost electricity and heat, reducing their reliance on the electricity grid whilst maintaining security of power.

New combined heat and power (CHP) plant at the University of York provides the campus with low cost electricity and heat, reducing their reliance on the electricity grid whilst maintaining security of power.

The new energy system will enable the University to fulfil its energy requirements and meet its target to use 10 per cent renewable energy to power the campus. The target was included in the University’s renewable energy strategy to reduce 48 per cent of its carbon emissions by 2020 in order to meet the requirements of the Higher Education Funding Council for England (HEFCE).

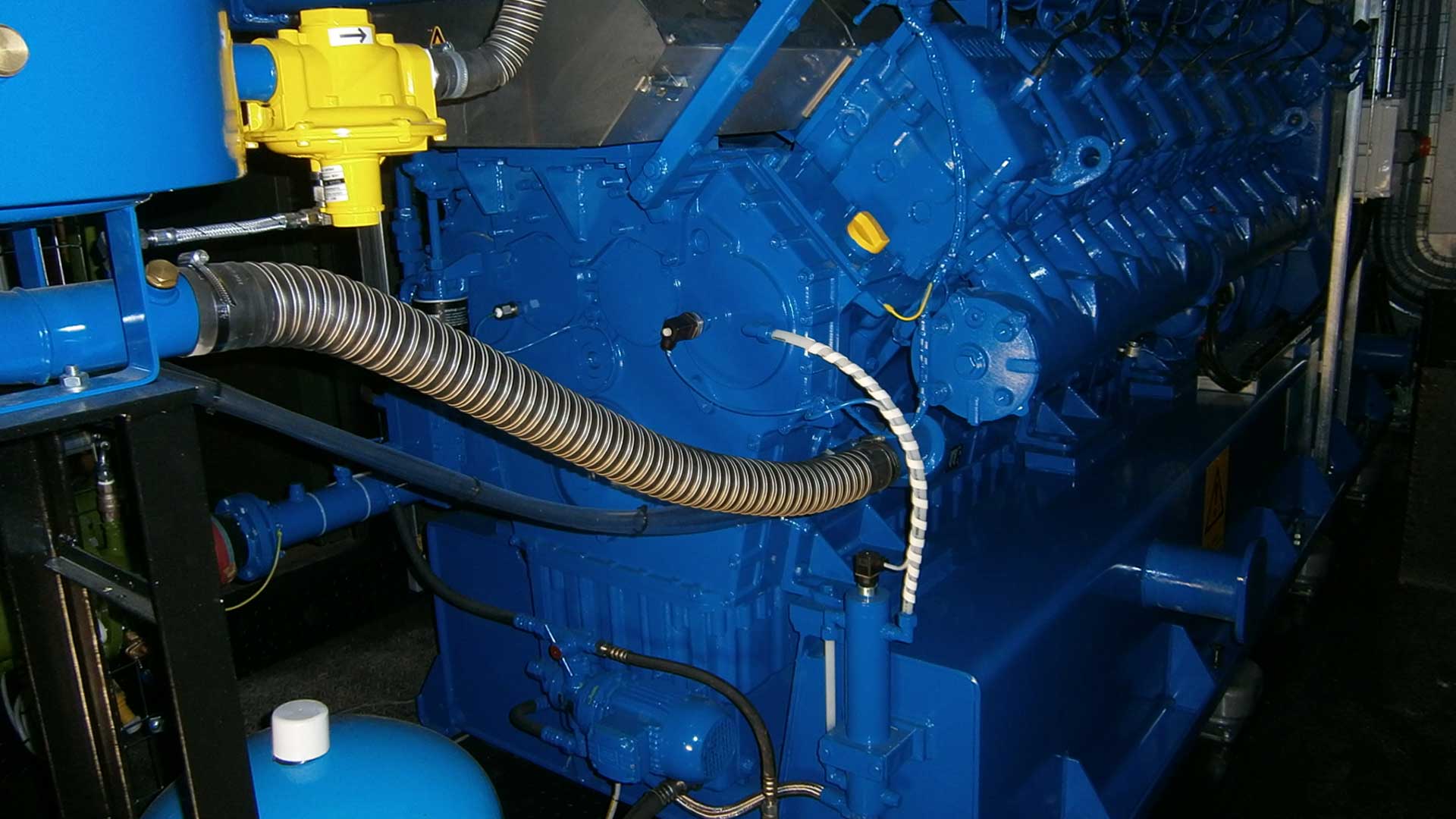

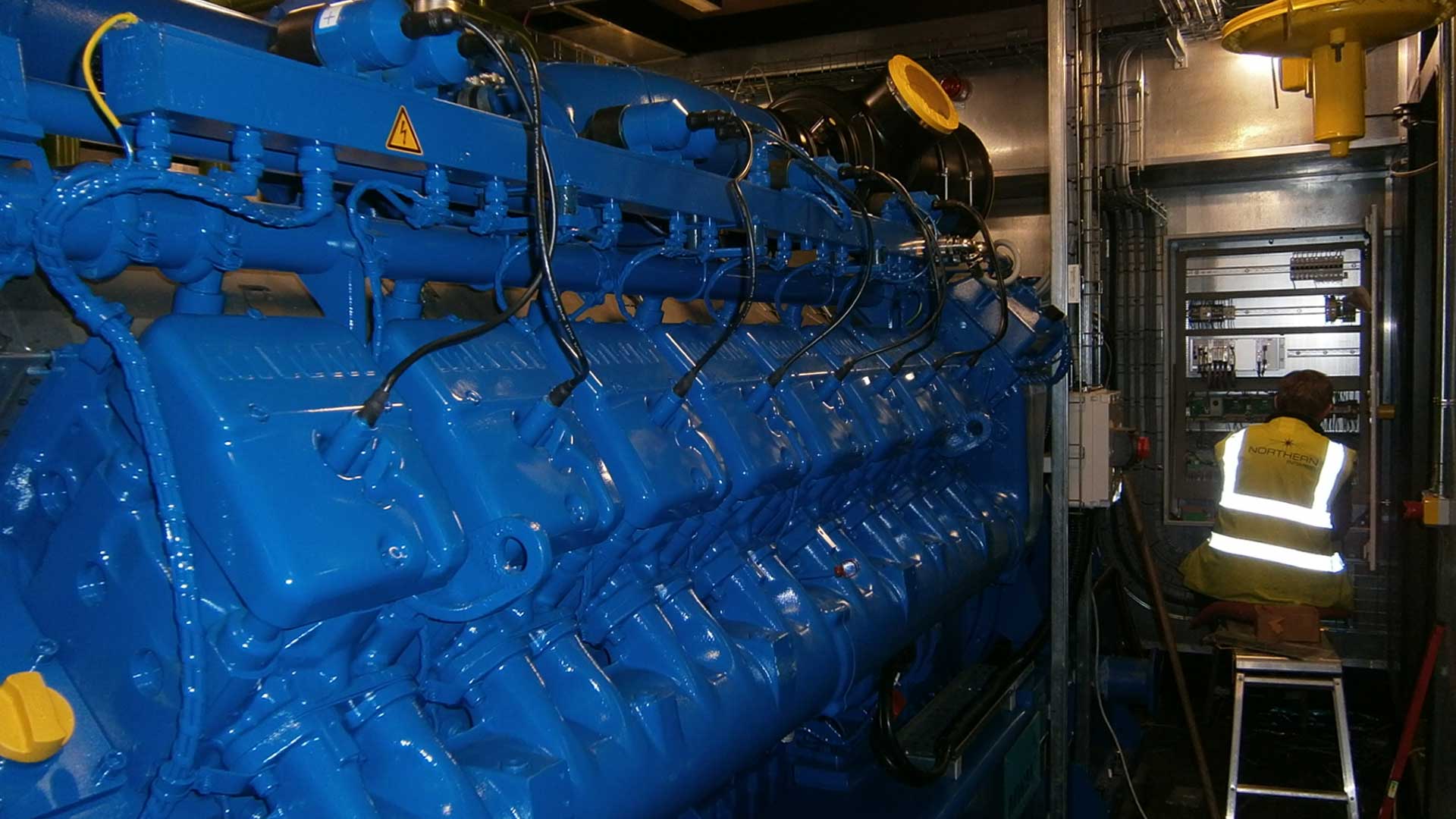

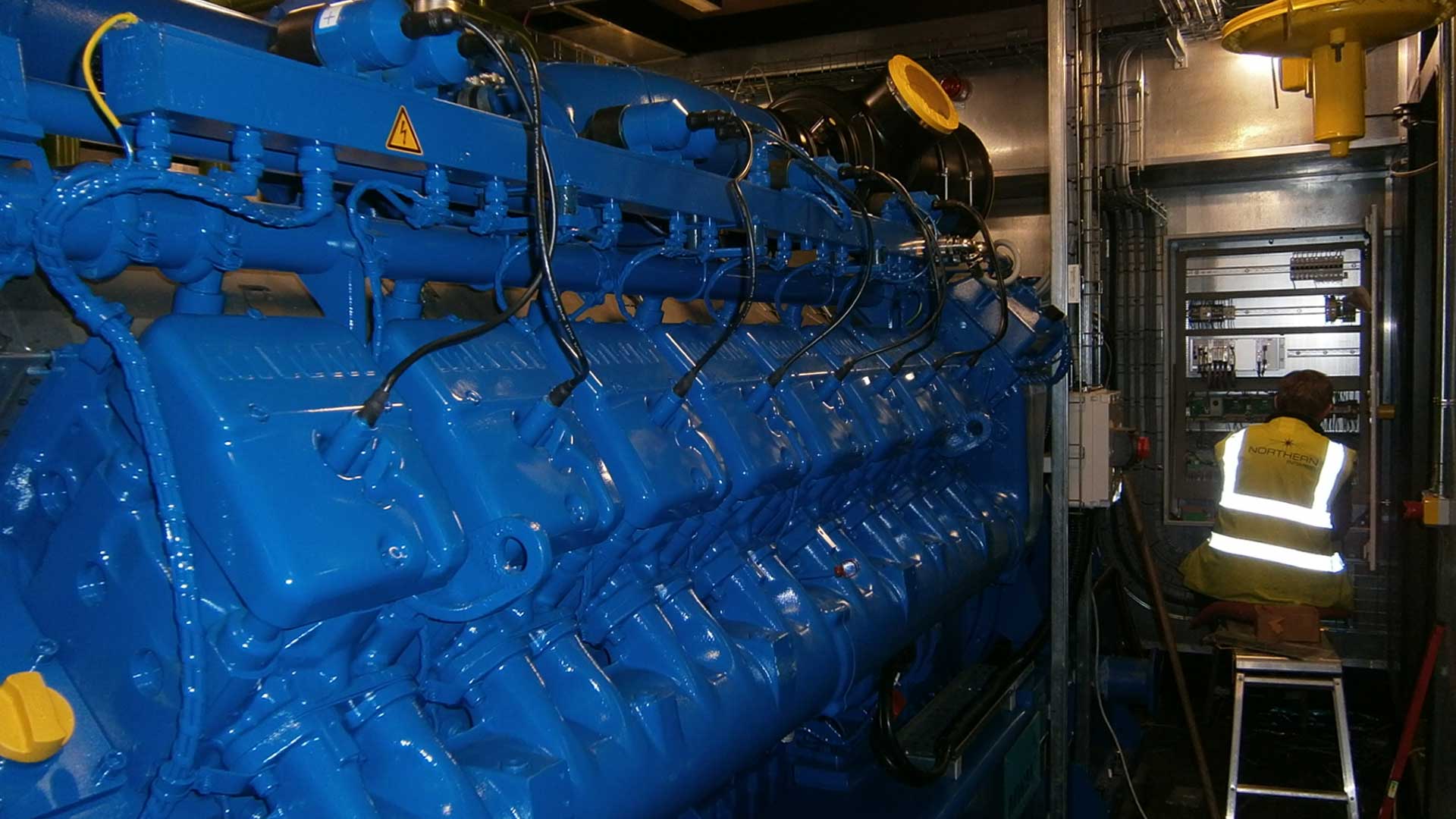

Following an extensive tender process the contract was awarded to Edina. The full turn-key contract included the design, manufacture, supply, installation and commissioning of two MWM manufactured gas engines.

The two 1.6MWe reciprocating gas engines replaced the existing engines housed within the University’s existing energy centre on the Heslington West campus.

The MWM TCG 2020 V16 engines were chosen based on their market leading performance in achieving maximum efficiency, reliability, flexibility and environmental sustainability, as well as offering low lifecycle costs.

Both 1.6MWe engines were containerised in attenuated acoustic enclosures at Edina’s manufacturing facility in Lisburn, Northern Ireland and positioned within the new energy centre to further reduce installation time and expedite site works.

To accompany the two CHP plants, an 850kW biomass boiler was installed on a separate site close to the Heslington East campus car park. It is understood that the biomass boiler will contribute around 7,000,000 kW/hr of thermal energy to the overall University demand per year and is capable of operating on both woodchip and wood pellet fuel types which can be locally-sourced.

Client:

Vital Energi

Location:

York, United Kingdom

Capacity:

3.2MWe

Operational:

2012

Manufacturer:

MWM

Packager:

Edina Group

Engine Type:

2 x 1.6MWe TCG 2020 V16

Primary Fuel:

Natural Gas

Queen’s University Belfast saves £948,000 per annum through CHP technology.

Read moreCranfield University reduce energy costs and emissions through Edina CHP.

Read moreNew district heating CHP energy centre supports University of Warwick to deliver efficient heat and power.

Read more

Copyright © Edina. All Rights Reserved.