Search

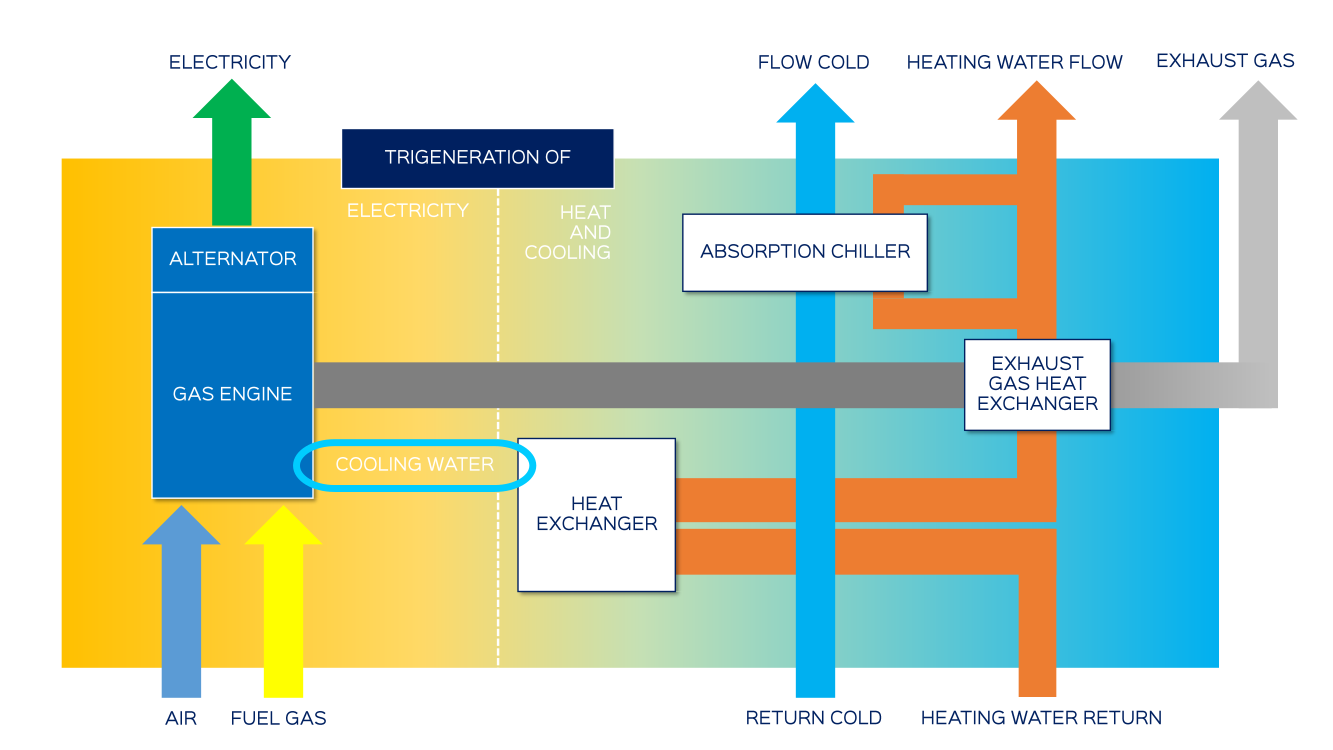

Trigeneration, or combined cooling, heat and power (CCHP), is the simultaneous production of electricity, heat and cooling all from a single source. The heat and electricity are produced by the normal operation of the Combined Heat and Power (CHP) unit, and an absorption chiller is used as a means of producing energy-efficient cooling from the heat output of the CHP.

An absorption chiller is a refrigerator that uses a heat source to provide the energy needed to drive the cooling process.

Absorption chillers do not have moving parts, as such there is little to no wear and tear on the technology and Operation and Maintenance costs are very low. In addition to this when considering it as part of a wider solution due to the technology the overall lifecycle costs are low. This makes it attractive on solutions whereby part or all the heat may not be required from the engine.

Typically, when an absorption chiller is included as part of a CCHP scheme you can expect a Coefficient of Performance (CoP) range of 0.6 – 0.8. If driven by steam this figure could increase the CoP from 1.2 – 1.4. This means that on average every kWth from the engine = 0.7kWcth at approximately 4°C.

Traditional electric chillers CoP is between 4 – 6. Thus, although they are significantly greater in efficiency, they require expensive grid purchased electricity to operate.

Absorption chilling whilst beneficial should only be considered on applications whereby the hot water or steam demand is little or none and the cooling demand is consistent and high.

Trigeneration is mainly used in infrastructure where there is a continuous or seasonal cooling demand to produce air conditioning and refrigeration.

Most commonly CCHP is now found in Data Centres and the Food and Drink sector where there is not the requirement for all or some of the heat generated from the engine. Whilst CCHP requires additional equipment it allows users the ability to reduce their cooling load from electric chilling and utilise the energy from the engine which otherwise may have to be destroyed through dry air coolers.

Trigeneration application is a cost effective and low carbon method of producing heat and cooling from the CHP and our Trigeneration installations have benefitted a number of high-profile projects including MediaCityUK, Citigen London, Trinity College Dublin, and many more.

Edina’s CCHP installations are applicable and feasible in both existing and newly built facilities. However, it is important to mention that the benefits and payback are greater when the CCHP solution is considered in the earlier stages of a project.

For instance, Trigeneration installation is best considered when:

A gas engine CCHP plant installation provides several substantial benefits, including:

High electrical efficiency

High thermal efficiency

Low operational costs

Simple electricity production

Enhances corporate ethics

Maximising engine and system overall efficiency

Fast project set up and installation

Flexible power opportunities

Lower electrical consumption from traditional chillers

Greater operational resilience – maintains security of power supply

Typical return on your investment payback in 3-4 years

Significant reductions in carbon emissions

Reduced energy bills – CCHP typically saving a minimum of 10% on previous energy expenditure

Future proofing sites from uncontrollable external energy factors – improves financial forecasting (energy spend) and business competitiveness

Edina can provide flexible finance options to suit your requirements, including low cost power purchase contracts and energy service agreements.

This could mean zero capital investment with instantaneous energy savings, thus freeing up CAPEX for alternative strategic investments.

Effective servicing and maintenance are essential to ensure high availability and efficiency of Trigeneration systems, helping to maximise cost and carbon benefits.

Edina's UK and Ireland engineering teams provide round-the-clock gas engine care - backed by 24/7 remote monitoring, the availability of genuine spare parts and MWM technical trained Edina field service engineers to ensure continuous operation of your power plant.

Edina is a market-leader in the engineering, installation and maintenance of Cogeneration and Trigeneration power plants and the exclusive distributor of high-efficiency MWM gas engines in the UK and Ireland.

We can either supply a single engine only or deliver the full EPC contract to include design, build, engineering, project management, integration of auxiliary equipment and balance of plant, engine commissioning and full 24 hours a day, 7 days a week, 365 days a year service and maintenance of the equipment over a 15-year life cycle.

Across our 35-year history we have requisite knowledge across the design, engineering, project management and maintenance of gas-engine fuelled power plants and have a growing installed capacity of over 740MW electrical across the UK, Ireland, Australia and India.

Copyright © Edina. All Rights Reserved.