MWM gas engines are built on a tradition of innovation for 150 years. Founded in 1871, the visionary and automotive pioneer Carl Benz accelerated a new era of gaseous fuelled engines.

Through cutting-edge technology and innovation, MWM has become one of the leading and world renowned in the field of gas engine generator technology and is owned by Caterpillar Inc.

The MWM range of gas engines are manufactured in Mannheim, Germany, and are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they achieve efficiencies of over 90%.

Innovation is core to the MWM ethos. MWM’s ongoing development and extensive research ensures the TCG series of gas engine technology continues to maintain its world-leading status.

Research & Development

Higher efficiency through intensive research from calculation to inspection

Operations

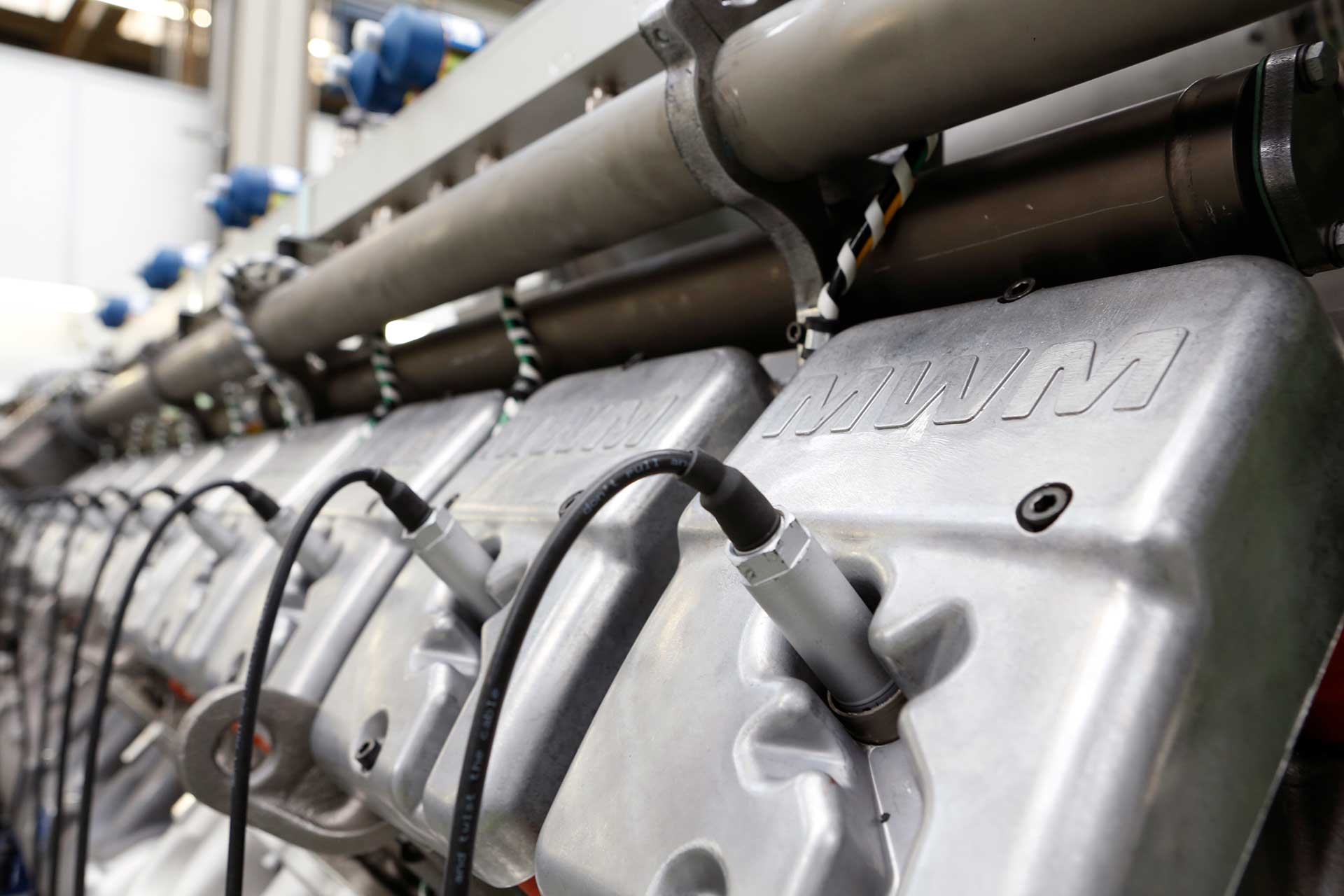

High quality manufacturing to achieve optimum benefits

Quality

Exceptional premium quality in all areas of the value chain

Sustainability

Long-term efficiency whilst reducing the use of natural resources

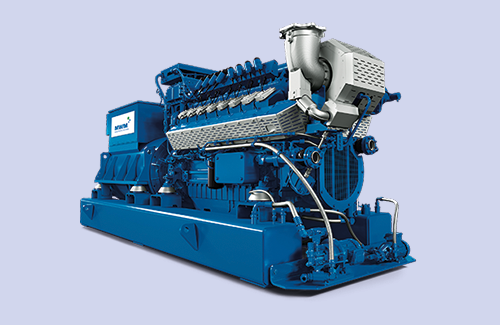

MWM gas engines are available from 400kW to 4,500kW electrical output and can operate on various gaseous fuel types including low carbon natural gas, renewable biogas, and are hydrogen ready.

The table below summarises the MWM natural gas range as per Medium Combustion Plant Directive (MCPD) requirement with engines based on equal to or less than NOx ≤ 250mg/nm3 @ 5% O2.

Heat recovery is configured for LTHW only (circa 90/70c).

All data based on NOx ≤ 250mg/nm3 @ 5% O2 as per MCPD.

Gas consumption based on LHV.

| Engine Model | Electrical Output (kWe) | Thermal Output Jacket and Exhaust (kWth) | Intercooler Heat-approx. 40°C (kWth) | Gas Consumption (kW) | Electrical Efficiency (%) |

| TCG 3016 V08 | 400 | 409 | 32 | 933 | 42.9 |

| TCG 3016 V12 | 600 | 648 | 37 | 1,422 | 42.2 |

| TCG 3016 V16 | 800 | 862 | 49 | 1,889 | 42.4 |

| TCG 2020 V12 (1MWe) | 1,000 | 1,102 | 53 | 2,382 | 42.0 |

| TCG 2020 V12 | 1,200 | 1,244 | 110 | 2,818 | 42.6 |

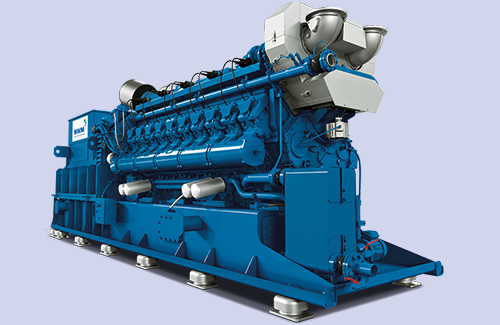

| TCG 2020 V16 | 1,560 | 1,650 | 138 | 3,698 | 42.2 |

| TCG 2020 V20 | 2,000 | 2,073 | 178 | 4,690 | 42.6 |

| TCG 3020 V20 | 2,300 | 2,255 | 196 | 5,231 | 44.0 |

| TCG 2032 V12 | 3,204 | 3,376 | 293 | 7,601 | 42.2 |

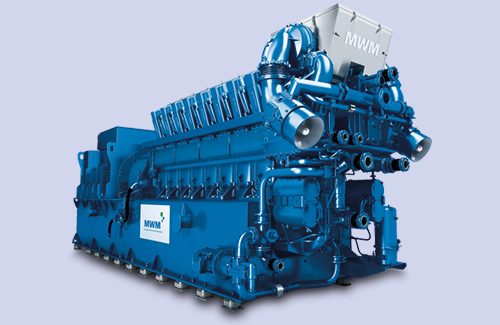

| TCG 2032 V16 | 4,500 | 4,524 | 274 | 10,295 | 43.7 |

| TCG 3042 V20 | 10,300 | 9,711 | 845 | 21,458 | 48.0 |

Edina generators have two distinct systems.

The boundary between the two systems must be clearly defined and understood.

The High Voltage infrastructure requires competent and formally authorised and nominated persons to implement and maintain. This is a legal and mandatory requirement within the Electricity at Work Regulations.

Managers/supervisors shall ensure that persons who are working on any part of the high voltage system are authorised to have suitable training and the appropriate documentation. For further details, we can provide the Edina Electrical Safety Rules.

World-renowned gas engine manufacturer MWM continues to innovate, ensuring the future of Combined Heat and Power (CHP) and its critical role within the global transition towards net-zero and beyond.

As such, MWM gas engines are capable of 25% blended-hydrogen CHP solutions. MWM have significant development experience in hydrogen-fuelled internal combustion engines for more than 20 years.

MWM gas engines can be configured to produce a multitude of power scenarios as per the below:

Base-load generation, standby power, and balancing reserve peaking plants.

Combined Heat and Power (CHP) or Cogeneration (Cogen).

Trigeneration or Combined Cooling Heat and Power (CCHP).

Recover CO2 through Quadgeneration.

A typical power plant is configured for continuous generation operating 8,000 per year, however, MWM gas engines can operate as flexible Peaking Plants to balance the fluctuating power demand within the local electricity network. MWM gas engines are also suited to produce electricity in parallel with the local electricity grid, operate in Island Mode configuration and Black Start operation.

Edina is the official UK and Ireland distributor for market leading MWM gas engines rated from 400kWe to 4,500kWe. Edina has held the distributorship rights since 2006, and has become one of MWM’s largest customers with a growing install base of over 600 gas engines delivering over 1GW electrical capacity across these territories.

We have installed gas engines across a multitude of industry sectors including Commercial, Industrial, Pharmaceutical and Healthcare, Hospitals, Universities, Data Centres, Agricultural and Farming. In doing so, our clients have reported a reduction in operational costs, reduced carbon emissions, greater operational resilience and improved business competitiveness.

Copyright © Edina. All Rights Reserved.