Search

Edina delivers mission critical power for the UK's largest teaching hospital.

Addenbrooke’s Hospital is one of the largest Teaching Hospitals in the United Kingdom and has strong links to Cambridge University. The University’s medical school based on the Addenbrooke’s site, graduates approximately 140 new doctors every year. The Hospital was founded in 1766 with £4,500 from the will of Dr John Addenbrookes. In 1976 the Hospital moved from Trumpington Street to its present location on the southern edge of the city and is now part of the Cambridge Bio-Medical campus.

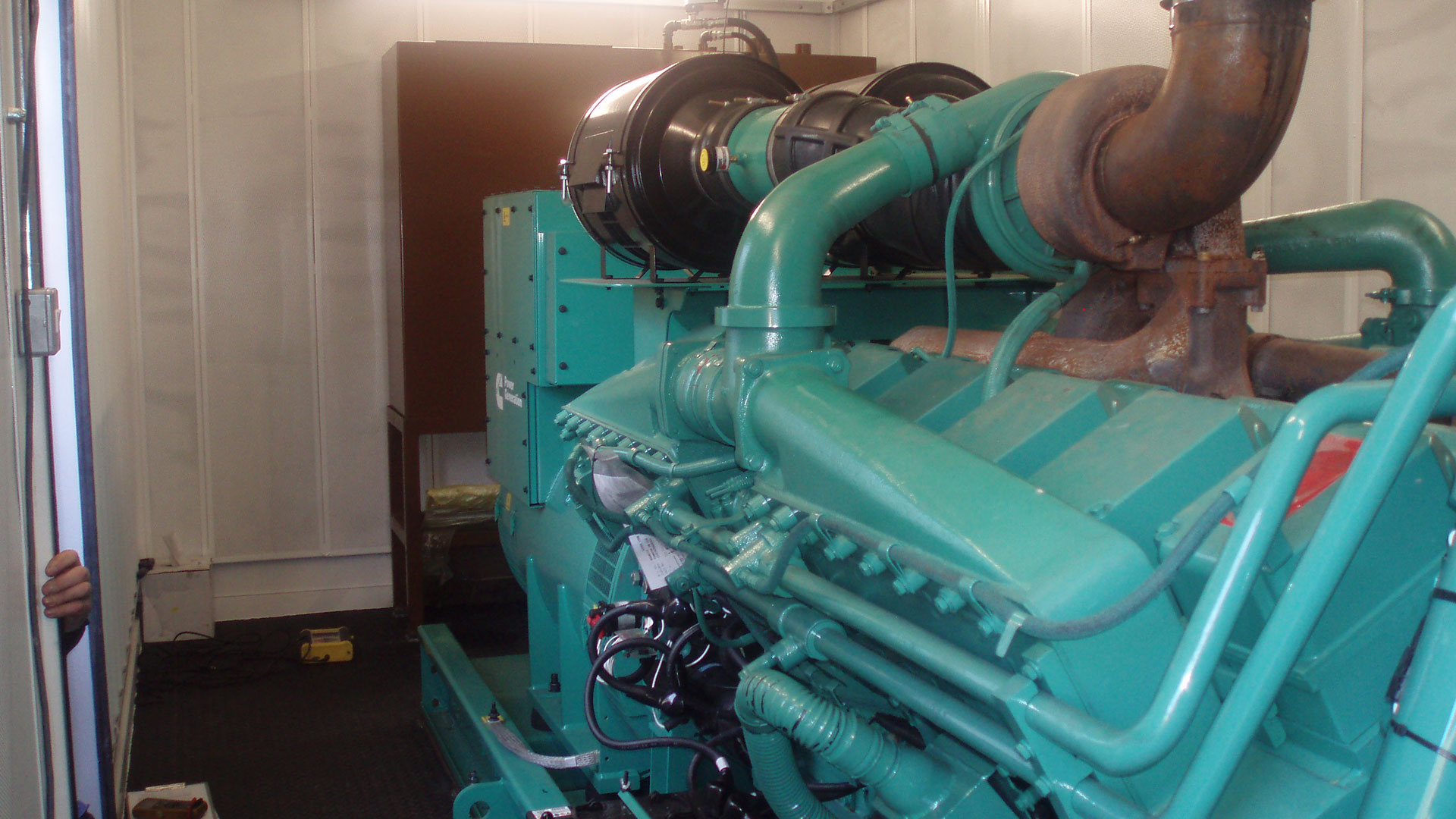

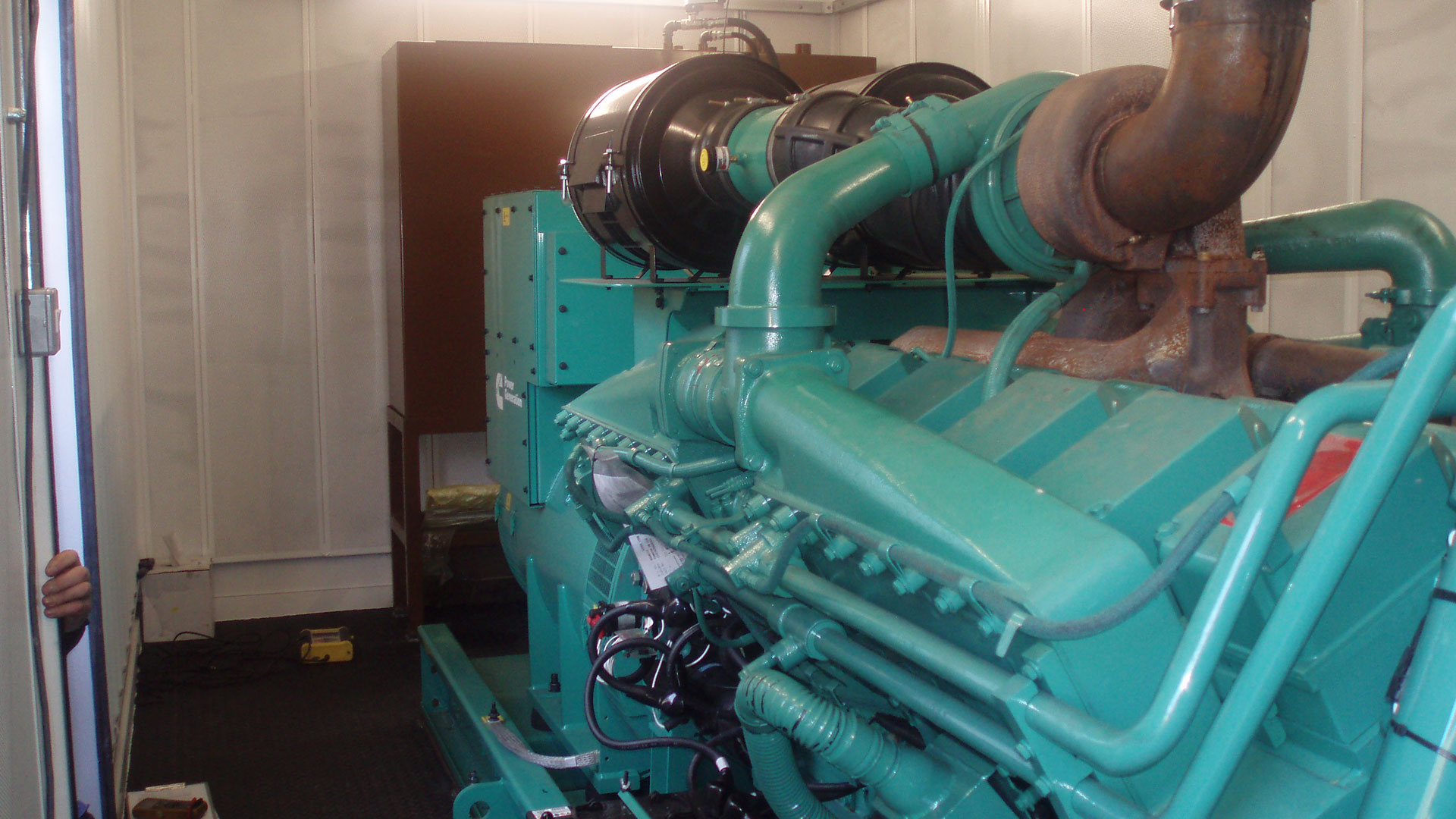

Edina tendered for the supply and installation of two new generating sets to provide emergency power to the Hospital’s C&D Blocks incorporating high dependency and intensive care wards. Edina’s bid was accepted and following initial meetings with Addenbrookes NHS Foundation Trust, Edina was appointed as Principal Contractor to design, supply and install the new generators and associated equipment. The project consisted of two 1500Kva diesel powered generating sets operating at 415 volts providing emergency power to critical care wards within the Hospital complex.

The generators have the facility to synchronise with the mains for “On Load” testing and to avoid a break in supply during the transfer back after a mains outage.

The first design consideration was the location of the new sets, as free space within a large Hospital complex is not easy to find. The roof top of the adjacent F&G Blocks was identified as a possible location. Edina appointed a Structural Engineer to establish if the roof and building structure would support the combined weight of the two generators, approximately 60,000kg. The roof location was approved with the addition of a supporting steel frame to spread the weight and transfer the load of the generators to the building structure.

To prevent noise and vibration transferring to the building and the wards directly below, the support frame was isolated from the building structure by means of anti-vibration pads. The generators were also housed within purpose built acoustic enclosures to further limit the noise levels to 65dB(A) at 1 metre with both generators running.

The second design consideration was the route of the Mechanical and Electrical (M&E) services from the basement switch room and courtyard of C&D Blocks to the roof of F&G Blocks. A purpose made cable ladder was installed on the external rear elevation of the building to support the substantial number of cables and the fuel supply lines required. To facilitate the M&E installation, a seven storey high scaffolding tower was erected in the courtyard; this provided the main access route to the roof of F&G Blocks and enabled the site works to be carried out with minimum internal disruption to the ward blocks.

The third design consideration was the positioning of the generators on the roof. The nearest suitable access road and setting up position for the crane was approximately 75m from the building. An 800 ton crane (one of the largest mobile cranes in the UK) was utilised to offload the generators and acoustic enclosures. The majority of the M&E installation was complete prior to the generator delivery and final connections of the services and commissioning of the set was completed within eight weeks of delivery.

Client:

NHS Trust, Addenbrooke’s Hospital

Location:

Cambridge, United Kingdom

Capacity:

2 x 1500Kva Prime Rated, Diesel Powered Generating Sets

Operational:

2013

Manufacturer:

Cummins

Packager:

Edina

Engine Type:

Cummins KTA50 G3

Alternator Type:

Newage Stamford

Primary Fuel:

Diesel

Edina maintains security of power supply at Northern Ireland’s most prestigious Grand Central Hotel

Read moreAn innovative method of waste disposal, which in turn creates its own energy, is being supported by Edina standby diesel power generation.

Read moreEdina delivers full turnkey installation to provide mission critical emergency power at Medway Maritime Hospital.

Read more

Copyright © Edina. All Rights Reserved.