Search

This CHP sizing article is the first in a blog series explaining the key considerations involved in specifying Combined Heat and Power (CHP).

This guidance is intended as background information for site managers, consultants, engineers and anyone else involved in the CHP specification process. To book a free CHP feasibility study or speak to a member of the sales team, please contact us today.

Combined Heat and Power (CHP) is an ideal choice in buildings that have a consistently high electricity and heat demand. In the right circumstances, CHP systems can improve energy efficiency, reduce running costs and offer quick payback times.

But if a project isn’t sized correctly, these benefits quickly start to evaporate. In this blog, we detail some of the most important considerations when determining the size of a CHP system to meet your site energy demand.

Incorrect sizing is perhaps the number one cause of sub-optimal CHP performance. If a CHP unit is too small or too large, it can result in organisations using energy inefficiently or losing out on significant financial benefits.

CHP specifiers have many variables to consider in calculating CHP sizing. It is critical to understand both the unique requirements of the site, along with the motivations of the project, including the cost and carbon requirements.

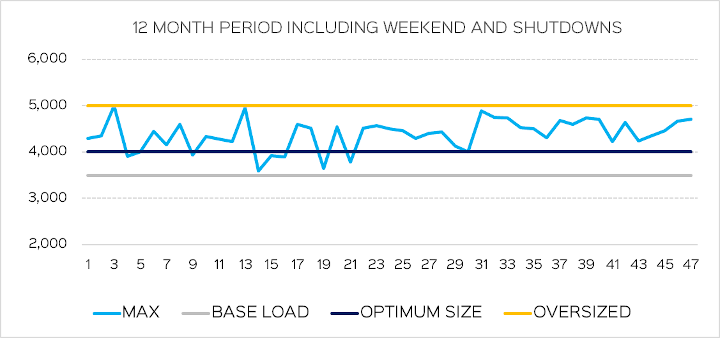

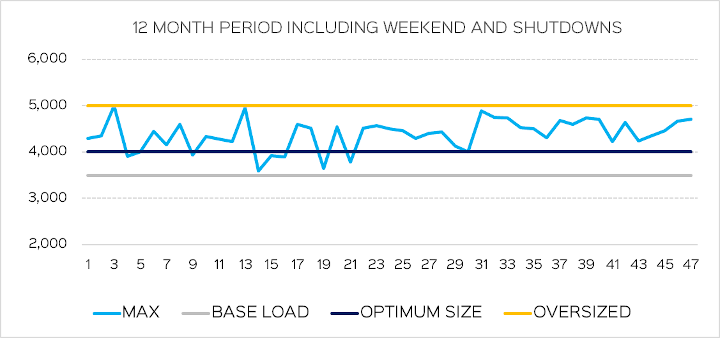

There is no need to size a CHP plant for the very highest peak energy demands and then for the system to run at a reduced level for most of the year. CHP generators are less efficient while they are operating at a reduced load.

While initial feasibility is straightforward and can be used as a good indicator for sizing a CHP based on the electrical demand of a site, it can open a host of questions and opportunities including:

Cogeneration, when sized to run at its most efficient, is supported by heat from existing boilers and grid electricity – to meet peak loads and provide back-up supply when the CHP is out of service for maintenance. Since CHP units are usually connected to the electrical distribution network, power demand in excess of the CHP output is readily met using imported power from the grid. Unless there is a requirement to run the site in isolation from the grid, for example at times of mains supply failure, there is no need to oversize for the odd occasion that the plant is required to meet excessive demand.

Sizing involves a fine balancing act that’s about meeting onsite demand for heat/cooling and electricity. While surplus heat must either be wasted or stored, excess power can be exported, but heat and electricity production can’t be decoupled, so getting the production ratios right is key.

CHP’s overall efficiency drops when heat isn’t used up, but it is generally more cost-effective to generate electricity on-site rather than relying on the grid. Specifiers must therefore reach for a careful balance between optimum efficiency and potential cost savings; maximising investment returns while minimising waste.

Edina’s MWM gas engines operate at extremely high efficiencies of 85% – 90%, almost twice as efficient as taking electrical energy from the grid and thermal energy from on-site boilers. This results in substantial savings on utility costs.

View Edina’s MWM CHP gas engine data sheets.

Undersizing and oversizing a CHP system each come with their own issues. If you undersize a unit, you won’t be generating enough power and heat to meet demand, meaning you will be more reliant on the grid and back up boilers and less likely to benefit from the cost-saving and efficiency advantages that come with CHP.

On the other hand, if you specify an engine that’s too big, you will overspend on capital and energy costs. Your system will also run at sub-optimal efficiency – leading to waste.

To maximise efficiency, it is generally advisable to size your CHP to meet the base load, which is the minimum level of demand for energy and heat over a given timeframe.

From a commercial perspective, however, the optimum engine size would provide slightly more than the base load. It would be sized to run at a full load for as long as possible, maximising the economic benefits of self-generation and resulting in only minor energy wastage.

If specifiers choose to maximise power output and waste heat, they do risk losing out on financial incentives that reward high efficiency ‘good quality’ CHP via the CHPQA scheme. These incentives include exemption from Climate Change Levy (CCL), eligibility for the Annual Investment Allowance and preferential business rates. Specifiers must, therefore, conduct a detailed financial assessment of the various options.

Read our guide to how to maximise financial incentives from good quality CHP

Correctly sizing a CHP system means closely matching a unit to a site’s energy load. This requires careful analysis of a site’s energy demand over time.

Energy consumption data can come from a number of sources. To build a clear picture of energy consumption, it is preferable to use half-hourly metering data or information from a building energy management system.

Plotting electricity and heat consumption over time will produce a pattern showing how and when energy is used. It will also show up variations in demand at different times of day, during the week and across the year. Mapping these variations is crucial to finding the optimum level at which a CHP unit should be operating at maximum output.

If you are trying to size a CHP system for a new building, then demand profiles can be estimated using a range of sources including design data, occupancy patterns, simulation modelling and benchmark profiles from comparable projects.

Using inaccurate energy data is one of the biggest causes of under or mis-sizing a CHP project, so take care to make sure this data is a true representation of real life.

It is also important that you consider potential site changes that could alter the energy demand profile. CHP systems have a typical lifespan of around 15 years so site expansion could have a dramatic impact on optimum CHP size. If you know that a site is planning to undergo expansion in the next few years, it may be beneficial to initially oversize the unit or make infrastructure allowances for an additional CHP to be retrospectively installed based on future demand.

Low-cost energy efficiency measures, such as building insulation, installing LED lighting and building energy management systems can also affect consumption. To avoid oversizing your CHP unit, it is normally advisable to perform these ‘low-hanging’ energy efficiency improvements or calculate their potential impact before pursuing a CHP installation.

The power and heat demand profile will vary over the course of days, weeks and months. In commercial applications, the heat demand profile has the potential to fluctuate more than industrial users that require process heat and steam. In the summer, for example, warmer weather is likely to reduce the demand for heat.

However, even when the heat generated exceeds the load, it can still be worth running the CHP at high load in order to benefit from the lower cost of self-generated electricity.

In certain circumstances, excess heat can be captured temporarily using a thermal store, allowing electricity production and heat consumption to be decoupled, or it can be rejected into the atmosphere using cooling towers or heat rejection radiators.

Excess heat can also be used to provide cooling via an absorption chiller in CHP systems that are configured for trigeneration. When atmospheric temperatures start to creep up during peak summer, absorption chillers could be used to generate chilled water, offsetting the energy used by electric chillers.

These Stories on Combined Heat and Power

Copyright © Edina. All Rights Reserved.